See

page 4

See

See

page 17

See

Legislation is set to change in Wales to ensure rented properties are fit for human habitation

It has recently been announced that the legislation, Renting Homes (Wales) Act 2016 will change, effective from 15th July 2022. The new regulations are designed to ensure that social and private rented properties in Wales are fit for human habitation, including the provision of an adequate Fire and Carbon Monoxide alarm system.

Section 91 of the Act places an obligation on the landlord to ensure that their property is fit for human habitation from the beginning of the tenancy and throughout. The requirements of the legislation are within The Renting Homes (Fitness for Human Habitation) (Wales) Regulations 2022.

The updates significantly affect the requirements for Fire and Carbon Monoxide alarms within rental properties. Under The Renting Homes (Fitness for Human Habitation) (Wales) Regulations 2022, landlords in Wales must ensure that there is a working Smoke alarm on every storey of a property, e.g. hallway and landing; in addition, all Smoke alarms must be mains powered and interconnected with other Smoke alarms in the property. Landlords should refer to BS 5839-6:2013 for the recommended installation of the required Smoke alarms, however Aico would encourage landlords to reference BS 58396:2019+A1:2020. The manufacturer’s replacement date should also be noted to ensure the alarms remain fully operational.

Additional Smoke alarms can be installed in the property at the landlord’s discretion, for example, a larger property would benefit from additional Smoke alarms for greater protection and coverage. A landlord may also consider installing a Heat alarm in the kitchen.

The Renting Homes (Fitness for Human Habitation) (Wales) Regulations 2022 also requires landlords to ensure that a Carbon Monoxide alarm is present in any room which has a gas, oil or solid fuel burning appliance installed.

Aico’s National Technical Manager, Andy Speake, comments “The updated legislation is a great step towards ensuring there is adequate fire safety in rented properties. The enforcement of The Renting Homes (Fitness for Human Habitation) (Wales) Regulations 2022 is a positive move in the right direction and will ensure greater levels of protection for tenants in Wales.”

In total, there are 29 matters and circumstances set out in the Act which determine whether a rental property is fit for human habitation, examples including damp and mould growth, fire, Carbon Monoxide, excess cold and heat and electrical hazards.

For more information on the legislation, visit: https://gov.wales/fitness-homeshuman-habitation-guidance-landlordshtml#section-86350

Engel high-viz workwear helps save the environment

Abrand-new range of high visibility protective safety clothing with 50% of the material made from recycled plastic bottles has been introduced by workwear manufacturer Engel Workwear.

Called ‘Safety Light’, each item of clothing can be verified to consist of regenerated polyester fibres ultimately spun from a specific number of plastic bottles to make up 50% of its content.

This is combined with 40% cotton and 10% standard polyester (245g/m2) to produce a cool-to-wear, durable fabric. By using regenerated polyester which is equally as efficient as new, there are also significant consumption savings on energy, water and CO2

The Danish firm has worked closely with Unifi, one of the world’s most advanced recycling centres which transforms the recycled bottles into a polyester yarn called ‘REPREVE©’.

The smart, mix-and-match range

includes boiler suits (containing 37 plastic bottles), work-jackets (20 bottles), trousers (19 bottles) with Cordura kneepad pockets and elasticated waistband, biboveralls (23 bottles) and shorts (14 bottles).

All have many practical pockets and comfort-design features. There is also a specific selection especially for women called ‘Ladies Light’, all with the same benefits.

For more information, contact Gareth Bladen

T +44 (0)7759 520034 gbl@f-engel.com

www.engel.eu/en

YouTube: https://youtu.be/nc2se7xKKlE

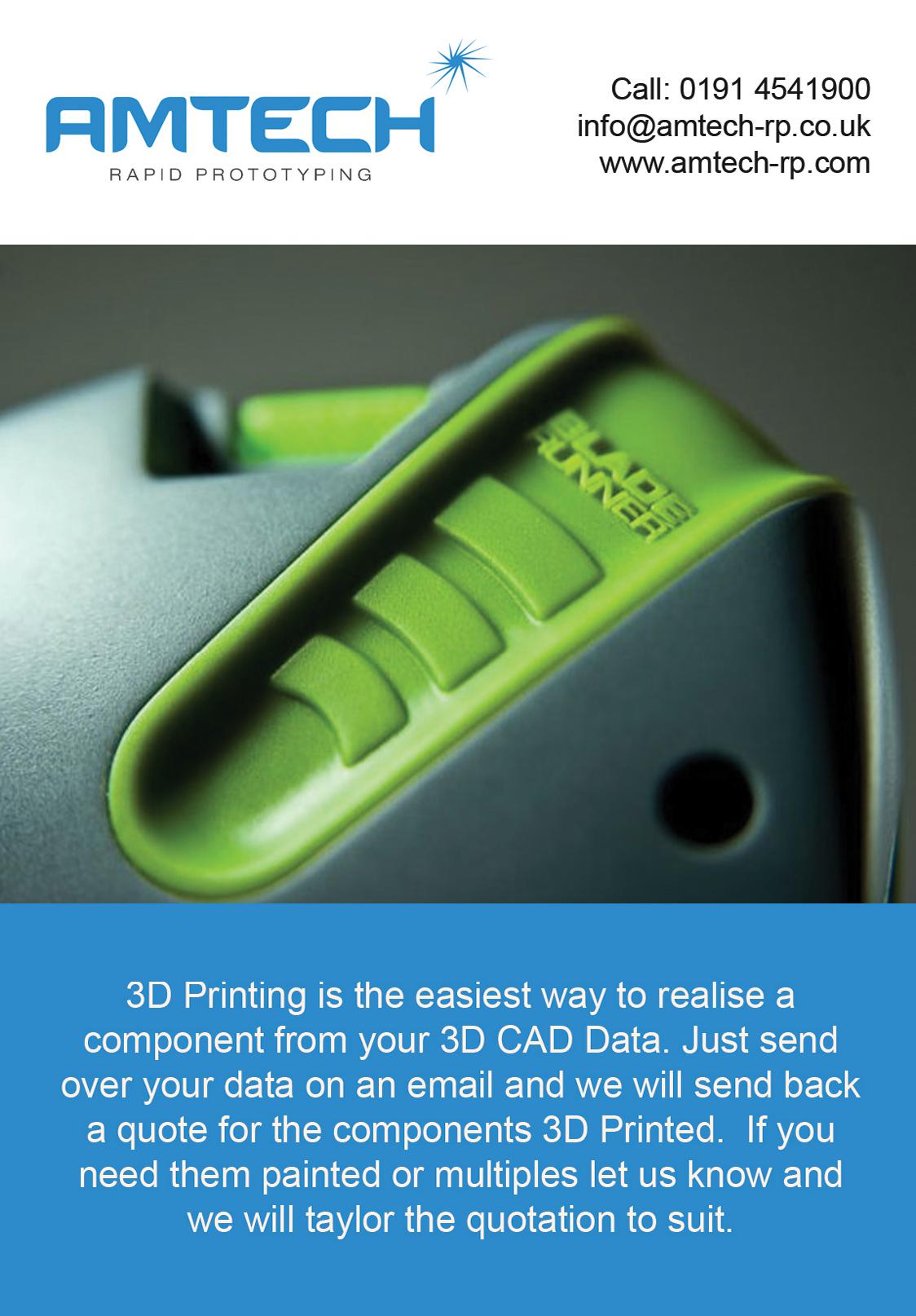

Inside this Issue Contents ECO PHYSICS AG Environment, Health & Process Control

them on

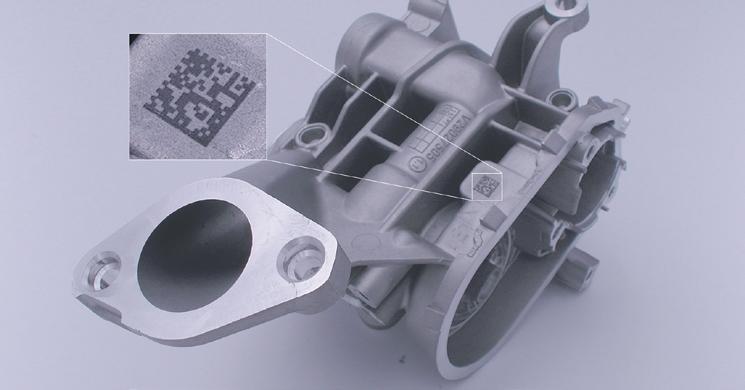

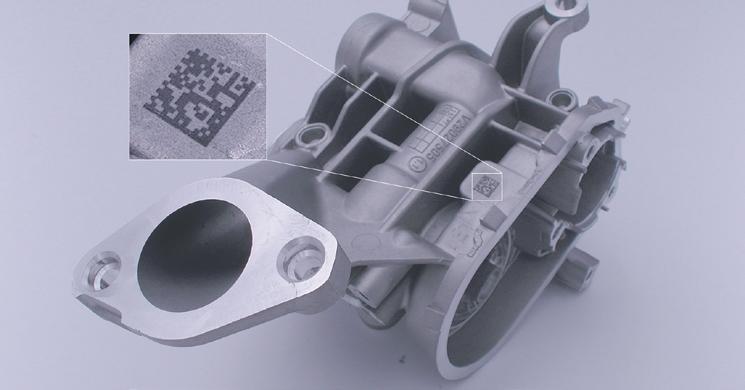

SIC Marking Ltd Marking Solutions

page 11

them on

Forteq UK Precision Plastic Technology

them on

EyeC Inspection Systems

page 29

on

2-4 Editor Recommends 6-9 CHEMUK Show Preview 12 Heating, Ventilation & Air Conditioning Update 15 Association of the Year 17 Marking Solutions Company of the Month 19 Inventory Management Solutions Company of the Month 21-25 Electronics Update 20 Precision Plastic Technology Company of the Month Follow us on Twitter @inu_uk Tel: 01562 756960 | www.industryupdate.co.uk | March 2022 | issue 236

them

Editor Recommends

MARKET LEADING PAVING BRAND GEOFIX® ONLY AVAILABLE FROM BOND IT

From 14th February we are pleased to announce that Bond It have acquired the sole distribution rights for the market leading Geo-Fix® All Weather and Geo-Fix® Original Paving Jointing Compounds.

When Geo-Fix Original was first brought to market 25 years ago, the paving industry was a completely different landscape compared to today. With traditional cementitious jointing products causing huge problems for Local Authorities and contractors, it soon became clear that an alternative solution was required.

After listening to the needs of the paving industry, Geo-Fix® developed a new technology using sand polymers to create Geo-Fix® Original brush-in jointing compound – a truly original product that revolutionised traditional jointing methods. In 2013, the range was enhanced to include Geo-Fix® All Weather jointing compound, a superior brush-in sand that can be used in all weathers, and now offer a selection of beautiful coloured sands to complement all designs and tastes.

Geo-Fix® is a ready mixed jointing that is simply brushed and compacted in to joints with minimal effort. Available in 2 versions, Original in 20kg buckets in Buff and Grey and All Weather in 14kg buckets in Stone, Mid Grey, Anthracite, Graphite and Slate Grey.

Bond It are a British manufacturer with 20 years’ experience manufacturing and supplying the construction, building and DIY markets.

John Andrews Director of Geo-Fix® stated; “We are delighted to be working with Bond It to distribute the Geo-Fix® range, the team are committed to providing exceptional products and service and I am confident together we will produce even greater opportunities for our customers.”

Dean Morgan Managing Director of Bond It says; “Geo-Fix® jointing compounds are recognised brand leaders and will be a perfect fit alongside our extensive Drive Alive range of products.

In addition, we are committed to ensure a seamless transition and service for all customers both existing and new and feel this is a huge opportunity for Bond It to penetrate into new markets.”

All Geo-Fix® products will all be available through Bond It through an authorised network of approved merchants and stockists throughout the UK and Ireland.

Contact 01422 315300 or email sales@bonditgroup.com for more information.

Megaman® launches its latest high bay offering – GEO 2

Global lighting manufacturer Megaman® has expanded its impressive product portfolio with GEO 2, a new and innovative integrated LED high bay lighting system. GEO 2, which can be controlled remotely for ultimate ease of use, provides a durable and energy efficient lighting solution, ideal for all indoor commercial high ceiling areas including halls, warehouses, retail and exhibitions.

The latest adaptable fixture from Megaman, the new GEO 2 has been designed with a passive cooling structure and lightweight graphene housing. This ensures it cannot overheat and increases

the product’s energy efficiency. GEO 2 also has an impressive L70B50 50,000hrs usage at Ta40ºC and is highly vandal resistant, with a rating of IK08, as well as an IP65 rating for dust and water resistance.

Furthermore, the cost-effective GEO 2 has a high luminous efficacy of 165 lm/W, allowing for significant energy savings in comparison with traditional high bays. Flicker free, the product maintains a consistent output.

GEO 2 is also available with a motion sensor remote control, affording customers the versatility and flexibility to gain instant control over their lighting and energy use.

Other optional accessories include a 1-10V dimming module, IP65 rated dimming wire and a motion sensor kit.

www.megamanuk.com

Industry Update is sponsored by EyeC – see them on page 4 2

Editor Recommends

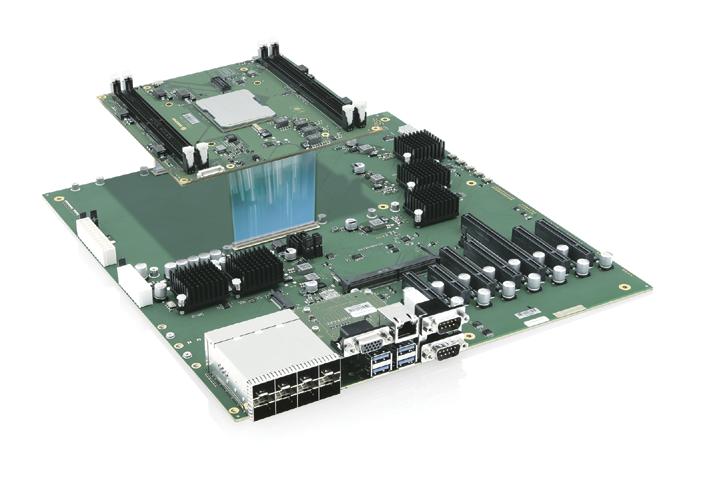

BEC Distribution Limited provides unmatched lead times

In this issue of Industry Update, we have chosen BEC

of High Current Power Inductors, Power Inductors, Chip Inductors, Common Mode Choke, Line Filter, Transformers, Resistors, Terminal Blocks, RJ45 connectors and LAN Magnetics.

The company offers premium drop-in alternatives for TOKO/MURATA, Sumida, Coilcraft, Cooper, Bourns, Vishay and many more. With advanced knowledge and technical information of its franchised product range, BEC Distribution Limited has created a reputation built on reliability, efficiency and excellence for its customers.

From its location in Buckinghamshire, BEC Distribution Limited ships all over the world. The company has

developed significantly since its inception and the appointment of John Dodds as Sales Director, who has developed the business to serve the electronic components needs of its customers through cost effective prices, enviably quick response times and excellent customer service levels. BEC Distribution Limited is able to offer a tailored solution to meet each individual client’s needs, while also offering the quickest lead times on the market.

A main focus for BEC Distribution Limited is its diverse offering of discontinued inductors for end-of-line (EOL) products. After noticing a gap in the market for its clients, BEC Distribution Limited saw that its clients

within the industry, were left waiting up to 30 weeks for some manufacturers to deliver their desired parts.

Determined to provide a solution, BEC Distribution

Limited now offers replacements for obsolete TOKO/ MURATA including EOL types for TOKO 8RHB2, TOKO 8RB, TOKO 10RB, TOKO 8RBS, and many more. Resulting in no more long lead times, BEC Distribution Limited is able to offer its customers EOL passive components to help buyers and engineers in the Electronic Components industry facing EOL issues. In addition, alternatives for Shielded Power Inductors, Multi-Layer Ceramic Chip Inductors, Radial Peaking Coils, Open Wire-Wound Chip Inductors, and Thin-Film Chip Inductors are also available.

One of the biggest issues that most engineers and buyers face, is the discontinuation of products from manufacturers after 5-10 years, this creates an issue for industries such as aerospace, medical, surveillance and defence, where they require products that far exceed a minimum of 10 years.

Committed to solving these issues, BEC Distribution Limited provides the solution for engineers and buyers alike, with the ability to shorten lead times for these industries on many products. Furthermore, through the company’s strong stance on customer satisfaction, if a required component is out of stock, BEC Distribution Limited’s knowledgeable and experienced customer service team utilise their ‘outside the box’ thinking and product iteration, to track down and source the nearest matching alternative, ensuring that all clients projects run smoothly and efficiently.

A main advantageous benefit of BEC Distribution

Limited’s services is its flexible approach to manufacturing and its swift distribution, which enables lead times to be cut in half. BEC Distribution Limited offers a leaner approach to manufacturing, by using its extensive industry experience and knowledge, the company has been able to position itself into a very niche market, offering alternative products with reduce lead times and save on overall expenditure.

If you would like any more information, please see below.

T 01844 275824 sales@bec.co.uk www.bec.co.uk

Industry Update is sponsored by ECO PHYSICS AG – see them on page 11 3

Distribution Limited

Editor’s Recommendation.

Distribution Limited

franchised distributor

for our

BEC

is a

PumpMatic Pump Stations

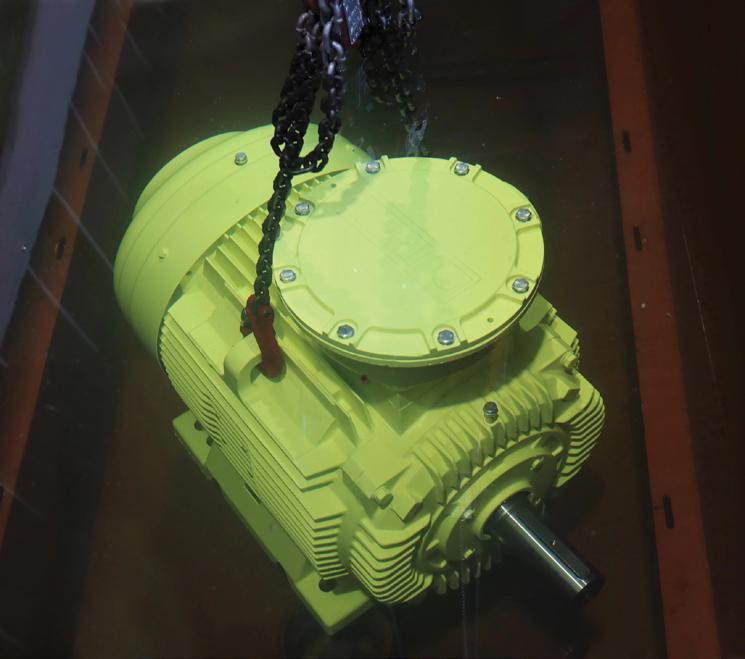

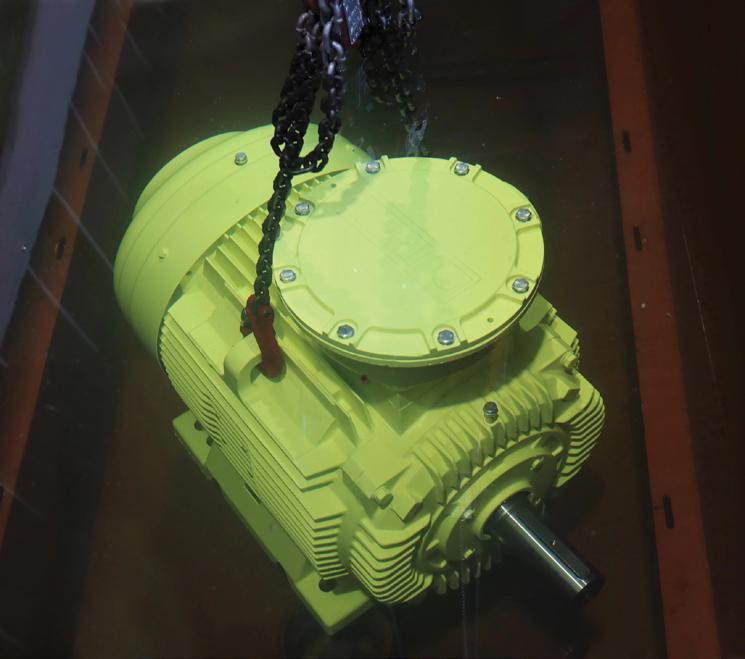

TÜV attestation for IP67 motors

Menzel

Elektromotoren manufactures IP67 low and medium-voltage squirrel-cage motors up to size

355. TÜV Süd has recently attested the dustproof and waterproof construction according to protection class IP67 of an entire low-voltage motor type series.

The series extends to outputs of 400kW and voltages of 1000V. In addition, TÜV Süd has attested Menzel’s procedures for IP67 testing, which the manufacturer also offers for its medium-voltage motors up to 11kV. Menzel builds IP67 motors with minimal tolerances, waterproof encapsulated cast-iron casings and terminal boxes. The German manufacturer stocks all basic components for dustproof and waterproof squirrel-cage motors and can realize very short delivery times for standard designs of IP67 motors. The motors are used worldwide, mainly in pump stations, flood-prone areas, food and drink

industries and maritime applications. They can be fully immersed at standstill for a period of 24 hours without any ingress of water. Subsequently, when water has receded, the motors are ready to be switched on again directly.

At the 2021 AEMT Awards of the Association of Electrical and Mechanical Trades, Menzel IP67 motors were voted the Product of the Year.

Meet Menzel at the Drives & Controls Exhibition in Birmingham, 5 – 7 April, 2022.

Contact T +44 (0)1664 500844 info@menzel-motors.com www.menzel-motors.com

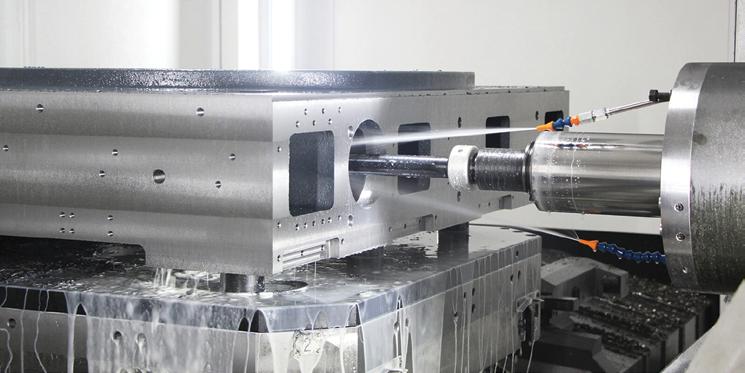

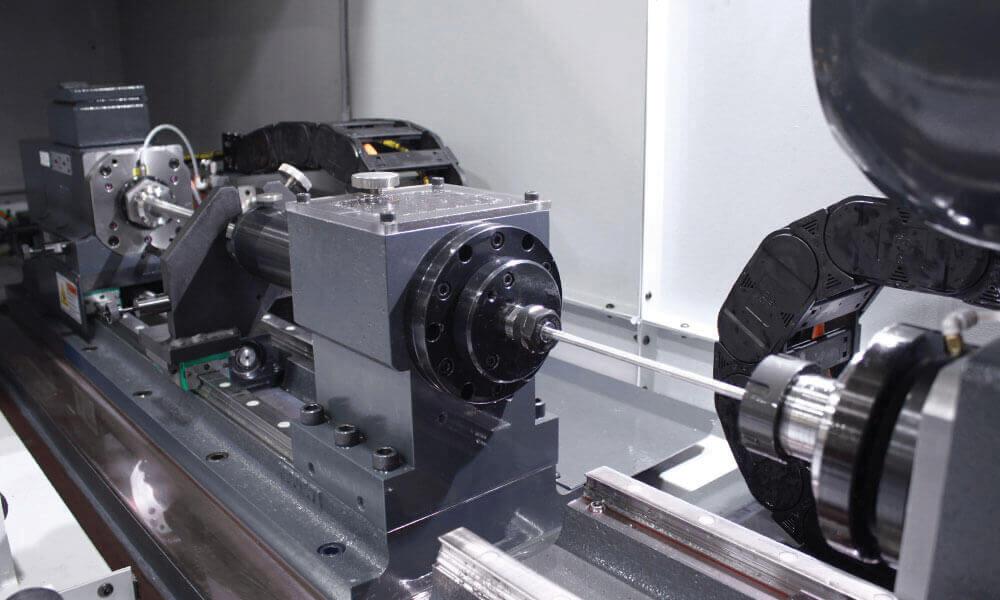

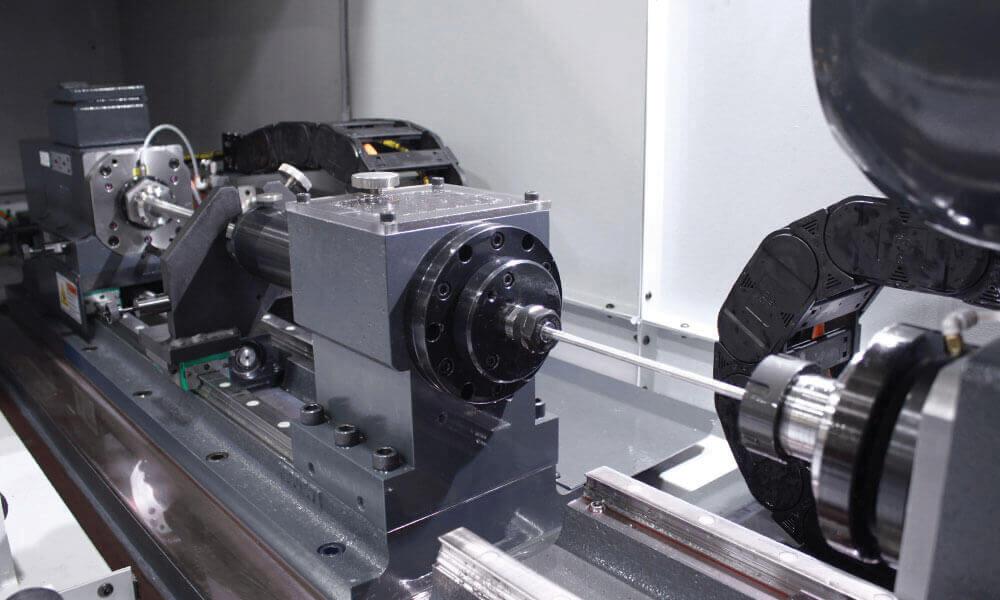

DF Precision Machinery

The

Industry Update is sponsored by EyeC – see them on page 4 4

Rotherham-based Go Tools Ltd continue to grow and invest in high quality machine tools and have recently invested in another two Okamoto ACC450AV precision surface and profile grinding machines from DF Precision Machinery. Technical director Steven Barrowcliff says: “After installation and operator training, the first two Okamoto machines soon began to make a significant contribution to our surface and profile grinding work. In addition to high precision and surface finish, their ease of use and speed has resulted in the machines becoming extremely popular with our grinding staff”. “High-standards of surface and profile grinding are critical to the quality of the tools that we manufacture, and these attributes are exactly what our Okamoto machines deliver. As we’ve been so impressed with our new Okamoto grinders, to help satisfy ever growing demand for our tools, we have since installed two further machines.”

Editor Recommends

Okamoto ACC450AV provides a table capacity of 450 mm X 150mm and allows fast and simple change overs. Minimum feeds of 0.001 mm on two axes with a high-visibility digital displays enables easy monitoring of all adjustments. A simple variable speed control to the grinding wheel enables it to meet the material and surface-finish requirements of each workpiece. sales@dfpmach.com

www.dfpmach.com

Housing specifiers and builders are discovering that, by utilizing the services of a specialist like Pump Technology Ltd., selecting the correct system for the job becomes fast and relatively simple. The pump station advisory team is headed up by the company’s own in-house drainage and pump consultant Steve Murphy.

accurate specification: The engineering team at Pump Technology Ltd. can specify the ideal tank for each application taking into account volume, size (diameter and depth), position of inlet or inlets and outlet, pumps and control panels. This means that specifiers and users are offered the best technical and commercial solution either immediately, or in more complex cases, within a few hours. PumpMatic, the “flexible” range: The company’s extensive PumpMatic range of modular tanks is suitable for many commercial applications such as schools, sport centers and many other such installations They are also ideal for garden offices, extensions, single and multiple houses. The manufacturing team maintain a core stock of tanks and equipment which can then be rapidly customized to suit individual site requirements at short notice and as needed.

cost of poor equipment selection: Pump Technology have learnt from years of experience that ultimately the reliable operation of a pumping station always starts with the correct equipment specification. It is extremely costly and difficult to put right mistakes after the installation of a below ground pumping station. Poor equipment selection can often lead to excessive, ongoing pump blockages, costly servicing and just the sheer hell of compromised usage, not to mention challenges with building standards Commissioning and Maintenance: All Pump Technology Ltd. equipment is fully supported by commissioning and maintenance teams across the country. This provides specifiers, installers and users with an end-to-end service to ensure ongoing peace of mind and reliability. For more information or assistance with sizing a pumping station for sewage, or drainage please contact the PumpMatic team. T 0118 9821 555 www.pumptechnology.co.uk

Fast,

The

Ranpak’s Curbside recyclable WrapPak® Cold Chain solutions provide thermal protection for up to 48 hours for e-commerce food delivery

Looking for a better Cold Chain solution for shipping of food products? Consider paper-based Cold Chain packing materials to reduce or eliminate plastic packaging that is hard to recycle, made from fossil fuels and takes hundreds of years to biodegrade. This is increasingly less acceptable to consumers. You may be surprised to learn how effective paper-based thermal protection products are whilst at the same time offering many cost ad sustainability advantages.

Do you have a warehouse full of existing thermal protection solutions like EPS boxes? While EPS boxes and other plastic-based thermal protection solutions, or even wool- or cotton-based solutions or denim liners, are certainly an effective thermal protection approach, they also take up a great deal of space, both in your warehouse and in the

product shipping process. Plus, their end-of-life disposal comes with many sustainability issues. Paper-based thermal protection is a so much better choice for products requiring thermal protection for up to 48 hours. Convert your operation to this more sustainable and costeffective choice with an on-demand system that produces paper pads on request. Get a custom box including Ranpak’s thermal solutions with the most sustainable Recycold cool packs in combination with the thermal paper packaging.

For more information visit: Keep it cool | Ranpak or contact and via email: eu.info@ranpak.com

https://Ranpak.com

Recyclable pouches join the family of McCoos

How can a recyclable pouch possible do justice to the Steven Brown Art’s - the McCoos?

When Deans of Huntly wanted to launch their range of Cookies in a recyclable pouch they approached National Flexible for ideas. They had the designs which are incredible, incorporating Steven Brown Art’s McCoos but were worried that a recyclable laminated pouch wouldn’t do the designs justice as some recyclable materials can have a ‘dull’ finish similar to polyethylene.

National Flexible had already had extensive experience of recyclable films and pouches and were able to help. The pouches needed to have intensity of colour not only in the main design but also in the photographs of the small packs on the front.

“We needn’t have worried. National Flexible understood exactly what we wanted to achieve. We are extremely happy with the pouches they look amazing!” Michael, Deans of Huntly.

T 01274 685 566

sales@nationalflexible.net

www.nationalflexible.co.uk

You are what you eat. So eat ‘Proper’.

Proper have moved into the fast growing snack bar category with a healthy alternative. The two flavours, Salted Caramel and Hazelnut Praline, are vegan and gluten free, have no palm oil and use ‘Proper’ ingredients.

The launch is in response to demand from shoppers for healthier on-the-go snacking options as the nation moves towards more mindful snacking.

The packs are made from matt and metallised film with 30% recycled content, meaning they are exempt from the Plastic Tax.

The Plastic Tax is being introduced in April 2022 to “provide a clear economic incentive for businesses to use recycled material in the production of plastic packaging, which will create greater demand for this material and in turn stimulate increased levels of recycling and collection of plastic waste, diverting it away from landfill or incineration”.

A full range of films with recycled content are available now.

Contact T 01274 685 566

sales@nationalflexible.net

www.nationalflexible.co.uk

Industry Update is sponsored by ECO PHYSICS AG – see them on page 11 5

Print & Packaging Update

CHEMUK 2022: Where the UK’s chemical industries

The organisers of the CHEMUK show are delighted to reopen its doors this April on the 11th & 12th May 2022 for CHEMUK 2022. It is the UK’s only trade show dedicated to bringing together multi-layer chemicals/chemical product development, specification and processing/ manufacturing communities with crucial supply chain supplier groups.

Welcoming over 2,400 visitors, over 350 exhibiting companies and a further 1,000 from across exhibiting teams all who graced the 10,000m2 expo floor creating a combined attendance of over 3,500.

Taking place over two days, the event will showcase supply chain sourcing, business networking, intelligence gathering, best practice and strategy development experience and an

meet

outstanding speaker programme featuring over 40 hours of content from guest speakers and panelists. These experts will be delivering topics that include sustainability/net-zero, post-Brexit and more.

This is our pick of the best exhibitors that will be exhibiting in this years show.

Further details can be found on this page and the next three pages.

www.chemicalukexpo.com

Assentech reduced the GWP of a 12” breather vent from 161 tonnes to 185kg

Assentech has been developing techniques to measure and reduce emissions from tank farms for over a decade. The key is keeping volatile compounds inside the tanks but allowing them to breathe when required such as filling/emptying and fluctuations in temperature. At all other times a breather valve should remain closed with minimal leakage.

These valves have

not

or

“We have a deep understanding of how breather vents work and how to optimise their performance. As they are modulating pressure

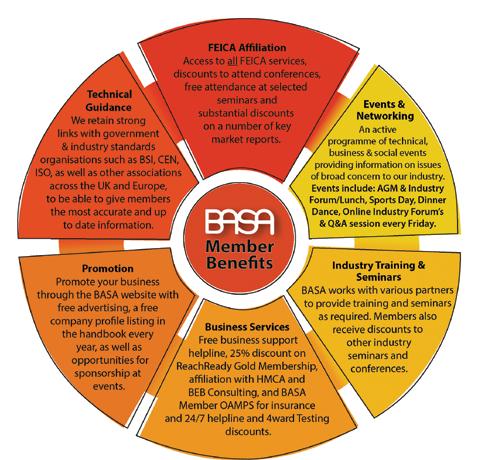

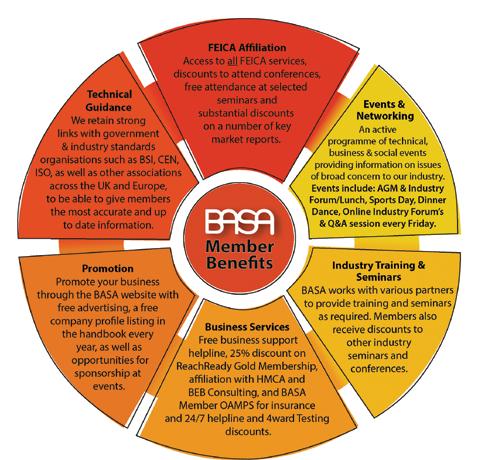

BASA

relief devices they can begin to open from as low as 75% of their set point. As many digesters run at 90% design pressure this overlap represents a large potential for mis-applied devices to leak excessively at standard operating pressures,” says Cox.

Two international standards ISO28300 and API2000 specify maximum leak rates for all production vents, ie. 0.014m³/h for vents up to 6”. The shame is that only 2 out of the 20 worldwide manufacturers test to this standard.

Unfortunately, the majority of breather valves that are installed at facilities do not seal and will allow huge volumes of vapour to release into the atmosphere. We are the only company which has

to the sustainability agenda whilst maintaining performance and durability.

BASA hopes to continue to reach more potential members, looking at ways to support its manufacturers post Brexit and help them to navigate potential new legislation and trade rules.

www.basa.uk.com

Reynolds Training Services

At Reynolds Training Services, our mission is to create a recognised career pathway for the Bulk Storage Operations sector, achieving this through a ‘Blended Learning’ approach, not only providing the knowledge, skills and experience, but also ensuring personnel learn how to learn throughout their work life.

Founded by John Reynolds in 2009, with over 35 years working within Bulk Liquid Operations, ‘Reynolds’ has developed training and competence assurance programmes relevant to the sector, from Apprenticeships, through to upskilling personnel, covering all aspects of operational including all modes of import and export operations as well as.

Training courses are underpinned by a range of National and Internationally recognised awarding bodies including NEBOSH. IOSH, and GQA. These are also joined by a wealth of bespoke development, ensuring that course content reflects your own policies and procedures.

to keep you safe, compliant and profitable.

Reynolds are, in conjunction with CATCH, founding members of the National Centre for Process and Manufacturing – a state of the art and UK leading Fully Operational Tank Farm and Process Plant Training Facility, offering ‘real world’ experience, giving us the ability to train and develop technical skills in Control Room, Process, Maintenance and Field Operations in a fully-emulated Process Operations Environment. Our cutting-edge equipment and controls align directly with industries within the UK and internationally.

Training and competence can be managed via our fully integrated Competence Assessment and Learning Management System, CALMcloud. Developed from scratch by our team of professional trainers and consultants to create a platform to effectively fulfil your training and competence management needs.

Visit us on Stand B6 and lets chat about how we might be able to help with your training needs. Reynolds

Training Services: Training for the Process Industries and More ...

www.reynoldstraining.com

CPL Activated Carbons

CPL Activated Carbons is a leading UK-based manufacturer and supplier of activated carbon filtration products and related services, including a wide range of Clean-Flo® mobile carbon filters, engineered in-house by our subsidiary CPL Icon. Wherever possible, spent activated carbon can be recycled via our RegenSys® process at our thermal reactivation centre at Immingham, where we have separate facilities for handling ‘amber list’ spent carbons (from chemicals, VOC, odour control, wastewater, biogas etc) and ‘green list’ carbon (from food and drinking water processes).

Reactivating spent carbons in this way offers a significant saving in terms of cost and carbon footprint. We have been supplying activated carbons for over 30 years, and our team of experienced and friendly experts is ready to help chemicals and pharmaceuticals producers solve their most challenging purification requirements, including wastewater treatment, VOC abatement and chemical purification. We are proud to have the latest ISO9001:2015 and ISO14001:2015 accreditations, as well as UK REACH registration. Check out our website or YouTube channel for more information about our wide range of products and services. We are “The Active Force in Carbon & Service.”

Come and meet the team at ChemUK2022 –Stand Number D16

T +44 (0)1942 824240 info@activated-carbon.com www.activated-carbon.com

Industry Update is sponsored by EyeC – see them on page 4 6

CHEMUK Preview

With its history dating back to its inception in 1983, BASA has excelled in its mission to become an umbrella organisation for UK adhesives and sealants manufacturers. We focus on technical and legislative aspects and on promoting awareness of the industry and technology by providing guidance on technical and compliance issues and creating a variety of networking opportunities for members, holding events using virtual platforms since March 2020.

is the voice of the adhesives and sealants industry’s and is an information source for manufacturers and suppliers. The association advocates on behalf of its members and liaises with Government regarding legislation and keeps Members well informed of UK, EU and International proposals and initiatives.

the growing concerns around the environment and using sustainable products and raw materials, BASA is dedicated to helping its members minimise harmful chemical usage and educate the public on the industry’s drive for safer products. BASA members work hard to formulate innovative products that positively contribute

BASA

With

immense flow capacity so if

functioning

set correctly can leak hundreds of tons of invisible GWP emissions along with company profits into the atmosphere.

the technology, knowledge and service capability

See us on Stand F37 at CHEM UK T +44 (0)1726 844707 info@assentech.co.uk www.assentech.co.uk

CHEMUK Preview

Compliance Services International (CSI) ROPAC

® UN Liquid and Solid Certified Pails offer unrivalled certification and quality to protect your product and the environment too.

The ROPAC® range of solutions enable the transport of high-value or dangerous goods by road, sea or air and meet the high-quality level requested by its customers.

ROPAC® packaging solutions provide safe protection for high value products

and hazardous liquids and solids. With their tough design and unique sealing system, they provide a protection from costly and dangerous leaks and spills. With an integrated tamper evident feature, it is the most innovative, market leading high performance and UN certified plastic packaging in the industry.

As part of the Schoeller Allibert Group, ROPAC® has been based in Romont since 1968. The plant in Switzerland

is well-known for the production of UN containers under the brand name ROPAC® and has been awarded with a Swiss and World Star Packaging Award for the design of its 5L UN liquid pack.

To request your FREE 5L solid of liquid pail, simply contact ROPAC® with your requirements.

Contact

T +41 26 651 9211 www.ropac-packaging.com

CSI’s mission is to serve our clients with scientificallysound, cost-effective, and timely approaches to regulatory compliance. Now that the UK has left the EU, we can help you comply with UK REACH to allow or maintain access to the UK market. Our team of experienced regulatory scientists deals with all scientific and regulatory aspects of REACH, including acting as Only Representative or Lead Registrant.

UK REACH services

t Full UK REACH strategy advice

t SIEF Coordination / Consortia Management

t Support with preparation of technical dossiers

t Lead Registrant services

t Chemical Safety Reports (CSR)

t Downstream User Import Notification (DUIN)

t Study monitoring

t New Registration of an Existing Substance (NRES)

t UK REACH account management

t Only Representative services

t SIEF Coordination / Consortia Management

t SIEF Coordination / Consortia Management

CSI also offers support for EU REACH through our Dublin office. Although EU REACH has been in force for nearly 15 years, Brexit changed the roles and supply chains of many UK companies exporting to the EU. CSI can assist in all aspects of EU REACH requirements.

Support with other Regulations/Industries

t Biocides - GB Biocidal Product Regulation (GB BPR)

t Plant Protection Products (PPP)

t GB Classification, Labelling and Packaging (GB CLP) info@complianceservices.com

www.complianceservices.com

CHEMUK2022 Stand M49

Diagnostic Tools That Will Revolutionise Industrial Network Maintenance

Preventing unplanned stoppages and simplifying troubleshooting is high on the agenda for anyone maintaining an industrial network. Procentec, the global leader in diagnostic and monitoring solutions, will be showcasing its practical tools to simplify industrial maintenance and prevent costly downtime for users of PROFIBUS, PROFINET, EtherNet/IP and EtherCAT networks.

“These solutions will cut down on unnecessary engineer call-outs, reduce the time you spend finding errors, and give you clear advice on how to troubleshoot,” says Pieter Barendrecht, CEO of Procentec. “They also offer a much more connected approach to fault detection and diagnosis. They will pay for themselves in no time at all.”

Upgrading diagnostics with the help of AI One of the highlights is undoubtedly SNAP Analysis. This unique, self-learning feature analyses the live data of an industrial network. It then gives an instant written diagnosis of a fault’s most likely cause, removing the need to manually interpret complicated oscilloscope images and messages.

SNAP also uses a predictive algorithm to recognise and learn from data patterns, enabling it to predict common network faults. It takes all the guesswork out of troubleshooting device issues and enables preventative measures to be taken.

For more information on Procentec’s wide range of solutions, visit their experts at stand C30

Sean Ogborne, UK Sales Manager T +44 (0)753 430 7696

sogborne@procentec.com

www.procentec.co.uk

Industry Update is sponsored by ECO PHYSICS AG – see them on page 11 7

ROPAC® UN Liquid and Solid Certified Pails

CHEMUK Preview

The Ultimate in Stainless Steel Processing

Suurmond UK Limited

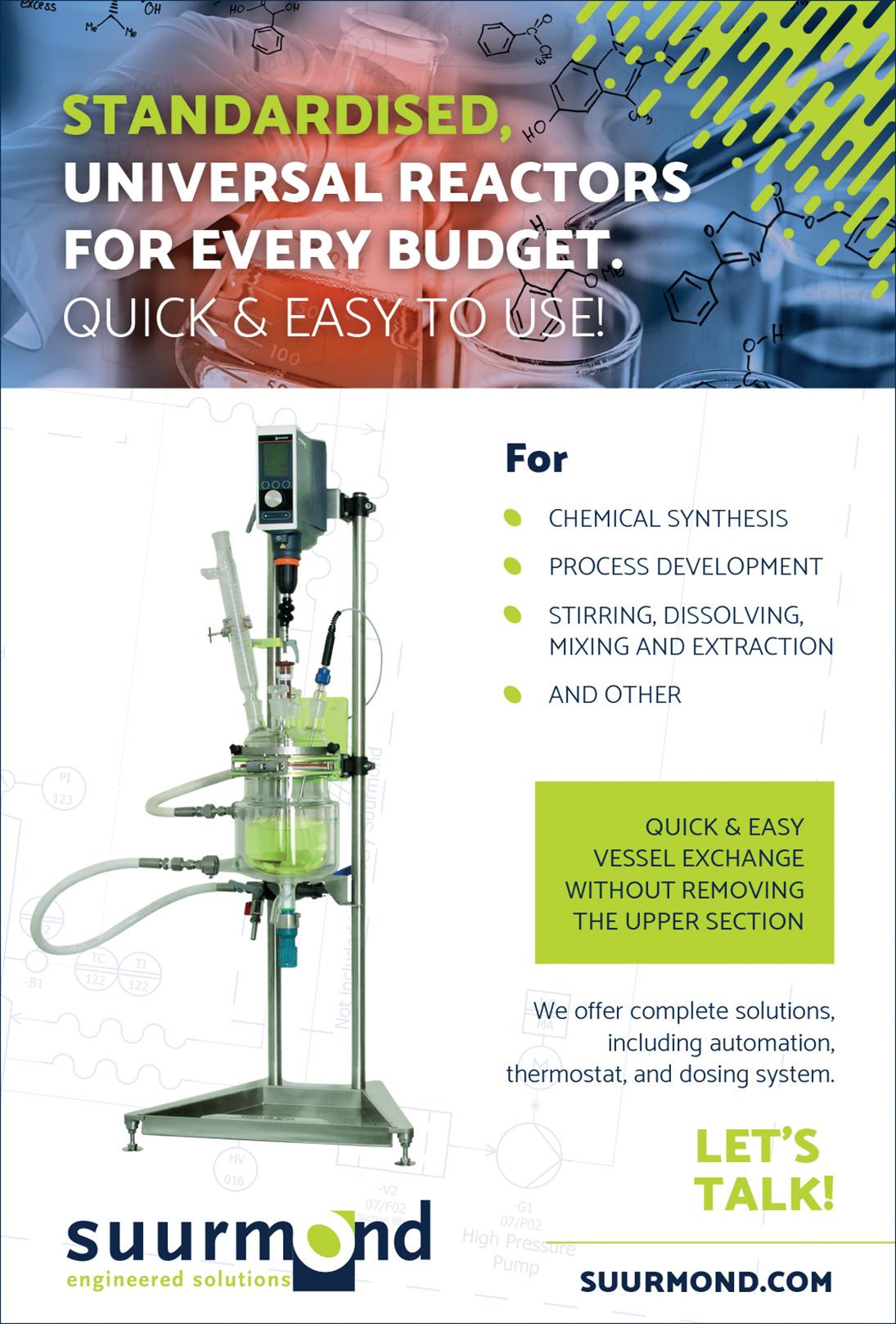

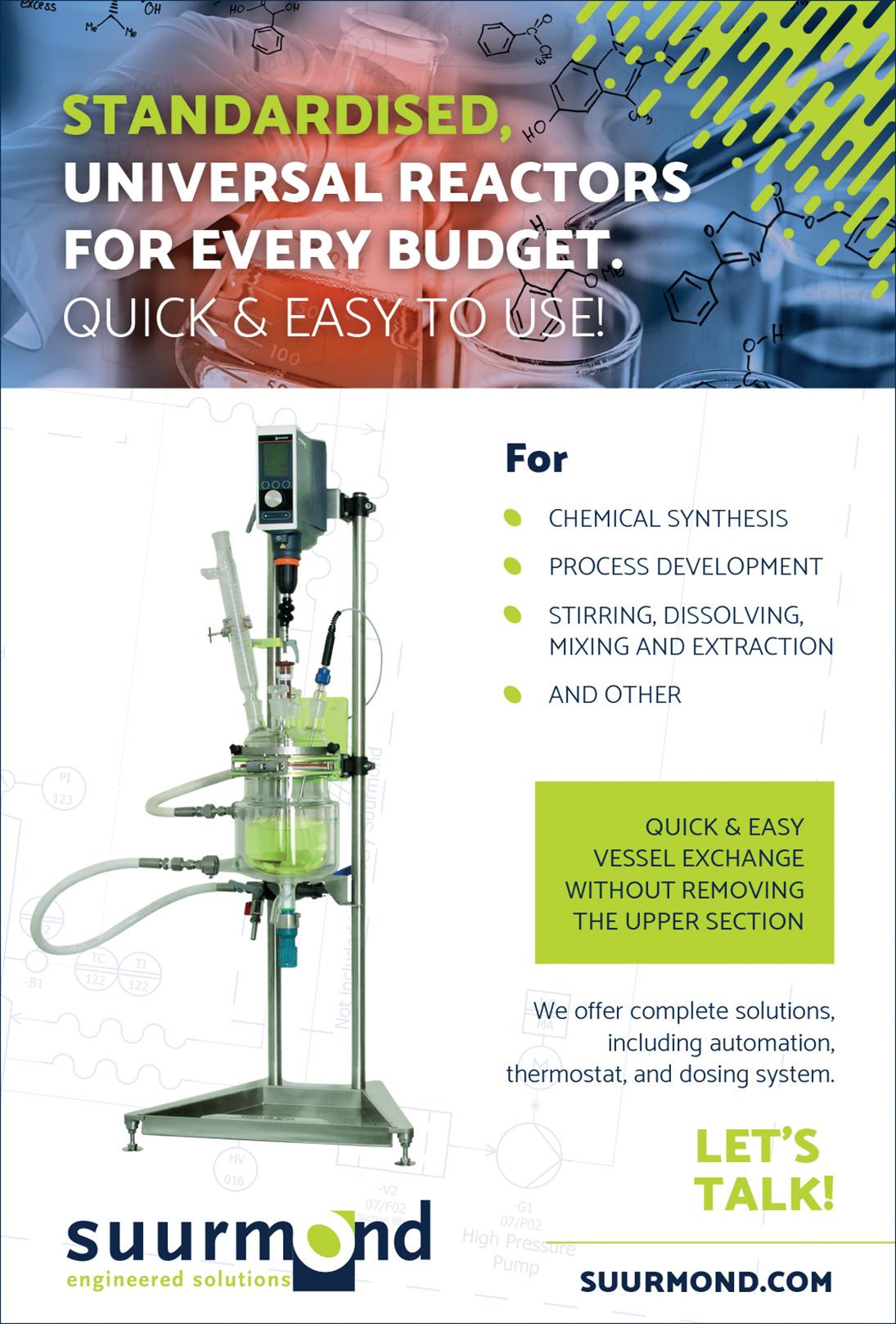

Suurmond UK Limited recently attended the ChemUK event at the NEC in Birmingham. A main feature of our booth was our NEW suurGLASS unit. suurGLASS is a standardised, universal reactor system for process development, chemical synthesis, stirring, dissolving, mixing and extraction.

The custom design of the support frame means that the vessel can be changed easily while the top cover remains secure mounted to the support.

The quick action clamp can be operated with one hand allowing the user to support the vessel for easy and safe vessel changes. With our system the top cover and all the accessories connected to it can remain in place.

Because our system is designed specifically for basic chemistry, we are able to offer a highly engineered solution at a lower price point than might be expected.

Basic specification:

Volume reactor vessel : 1 - 5 litres, using the same cover plate

Vessel materials: Type I, Class A borosilicate glass

Drip tray material: Standard in 316L

Stirrers: Anchor, propeller, impeller, turbine

Temperature: Up to 200°C

Pressure: -1 to +1 bar

Options: A wide range of glass accessories like burette, cooler, dropping funnel, various sensors

Contact us at 01386 423756 or at https://suurmond.com/products/suurglass

Ltd can reduce your metal consumption, please visit stand F19 at the CHEM UK show – we look forward to meeting you there!

For all enquiries, please contact Lee Nicklin Business, Development Manager:

T +44 (0)1204 368600

lnicklin@steel-dynamics.co.uk

www.steel-dynamics.co.uk

sera Technology

As a worldwide leader in dosing technology, sera Technology is a system provider of high-quality products and services for the dosing and feeding of chemicals and fluids. Indeed, with 75 years of experience, sera Technology is renowned for its excellent customer service and leading German engineering, offering some of the most robust pumps available on the market.

Safely convey & transfer with our new airPUMP, an Air operated diaphragm pump with an operating range up to max. 8bar / 900 L/min.

sera air operated diaphragm pumps are cost-effective, leakage-free positive displacement pumps. They have two diaphragms linked by a connecting rod. Compressed air is supplied alternately to the air chambers behind the diaphragms through an air control valve, so that one diaphragm is pushed forward while the other is pulled back (pressure/suction stroke). The special design of the air control valve ensures that the pumps can always be started up safely and there are no inconvenient downtimes. The valve balls open and close with the stroke rhythm of the diaphragms. Stand D3 www.sera-web.com

Industry Update is sponsored by EyeC – see them on page 4 8

Steel Dynamics Ltd, now part of the Steel Dynamics Group, is the UK’s leading Stockholder and Processor of Stainless Steel strategically located throughout the UK, supplying a range of mainstream profiles to complex supply chain solutions. We stock only premium quality materials from World Class EU mills. Our extensive stock range boasts over 5,000 tonnes of various Stainless Steel grades in thicknesses ranging from 0.5mm – 150mm. We are adequately stocked to support UK manufacturing during recent and uncertain economic climates. Due to ongoing substantial growth, Steel Dynamics Ltd has also invested heavily in the latest, state-of-the-art equipment to develop our cutting, milling, and pressing capabilities. Our most recent investments include the HAAS VF4 Super-Speed, Timesaver 22 Series and a completely bespoke 14m x 4m, dual gantry multi-head system Water Jet cutting machine! Demonstrating our wealth of expertise with over 200 years’ combined experience, Steel Dynamics Ltd purpose is to relentlessly work together with its customers to reduce their costs and help UK Manufacturing flourish. We believe in nurturing our relationships with all our customers thus, TSC is aimed at relieving the stress of managing material, identifying processing methods, handling and delivery from our customers. Our Total Service Concept is offered free with no up-front cost and offers a range of unbeatable benefits!

more information on how Steel Dynamics

For

Blended

At Blended, we have been supplying specialist chemicals and gases for almost 20 years. The company prides itself on offering the optimal ‘blend’ of speciality chemical expertise, exceptional service, and positive attitude that customers can rely on.

From Anhydrous Ammonia and Carbon dioxide to a line a glycol-based heat transfer fluids, a team of industry experts and a full-service testing laboratory, Blended are the ideal partner to supply your chemicals and gases. Over the years, we have developed strong relationships with our clients and

endeavour to provide the best, ongoing service with the food and drink industry, heating, and cooling sector and even wastewater treatment plants. Whatever the challenge, we have the equipment, resources, and people to meet your project needs.

Coolblend, by Blended, is a complete range of highperformance heat transfer fluids that can be used in a wide variety of applications requiring the need for glycol based heating and cooling liquids. Our new line of cleanings solutions: Serviceblend includes precleaner, biocide, and online cleaner as a highly effective

biocidal flush. This product works optimally with our glycol-based products but also as a stand-alone product for servicing and maintenance of equipment.

Call our team on 01652 680 555 to find out more.

CHEMUK Preview

Apex Pumps

Apex Pumps has been producing high specification centrifugal pumps since 1988, operating both within the UK and worldwide on installations where efficiency and reliability are of prime importance, and we have earned an enviable reputation for the quality and endurance of our products. Apex is able to produce bespoke centrifugal pumps to customers’ requirements on short lead times. The unique capability within the UK of having a foundry onsite and utilising UK sourced material were possible. The company has been built on its responsiveness to enquiries, customer’s requirements and delivery needs. We design and build all our pumps at our site in Bristol and are very proud to be a members of Made in Britain and the British Pump Manufacturers Association.

Apex Pumps ISF range offers an end suction pump conforming to ISO 2858 and ISO 5199. The ISF range is the ideal pumping solution for demanding applications such as chemical process and many industrial applications. A comprehensive range of 29 pumps sizes with many more configurations, high efficiency design and with low net positive suction head requirements. Available in a wide range of materials including stainless steel, Super Duplex and Nickel alloys for some of the most arduous chemical applications.

Apex will be showing at ChemUK stand E16 and are looking forward to meeting people face to face for the first time in a while and talk about your British made pumping solution.

www.apexpumps.com

LAUDA – Experts In Thermal Control And Measurement

Providing Innovative Solutions For Thermal Process Control, Chilled Water Applications, Water Baths, Freezers, Incubators, Shakers, Stills, Tensiometers, Viscometers And Contact Angle Measurement. LAUDA continues to provide an expanding range of feature-rich, future proof solutions with energy efficiency and connectivity front of mind, serving a diverse range of industries including chemical, pharmaceutical, biotechnology, oil and gas, composites, automotive, aerospace food & beverage, brewing, digital printing, laser and beyond.

LAUDA’s new range of water chillers has been designed not only to comply with the new Eco-design directive, but to surpass it through the innovative use of variable speed modules that automatically reduce their duty cycle in line with the cooling demand hence reducing energy consumption & running costs, giving a tangible return on investment for the user, while ensuring full compliance with the latest regulations on refrigerant (fluorinated) gases.

Further portfolio expansion delivers the new LAUDA

‘Versafreeze’ ultra-freezers, (deep-freeze storage down to -85°C), and higher power ‘Integral’ process circulators, (process control from -90 to 320°C with >25kW of cooling @20°C), with pressure overlay options to increase the working range of water/glycol up to 140°C. Beyond temperature control, LAUDA has a well-established suite of solutions for measuring viscosity and surface/interfacial tension aimed at the development of polymers, oils, and surfactants.

We look forward to hearing from you.

T +44 (0)1780 243118

info@lauda-technology.co.uk

www.lauda-technology.co.uk

www.linkedin.com/company/lauda-technology-ltd

www.facebook.com/LAUDA.UK/

www.twitter.com/lauda_uk

Find us on stand G52 at CHEM UK

Industry Update is sponsored by ECO PHYSICS AG – see them on page 11 9

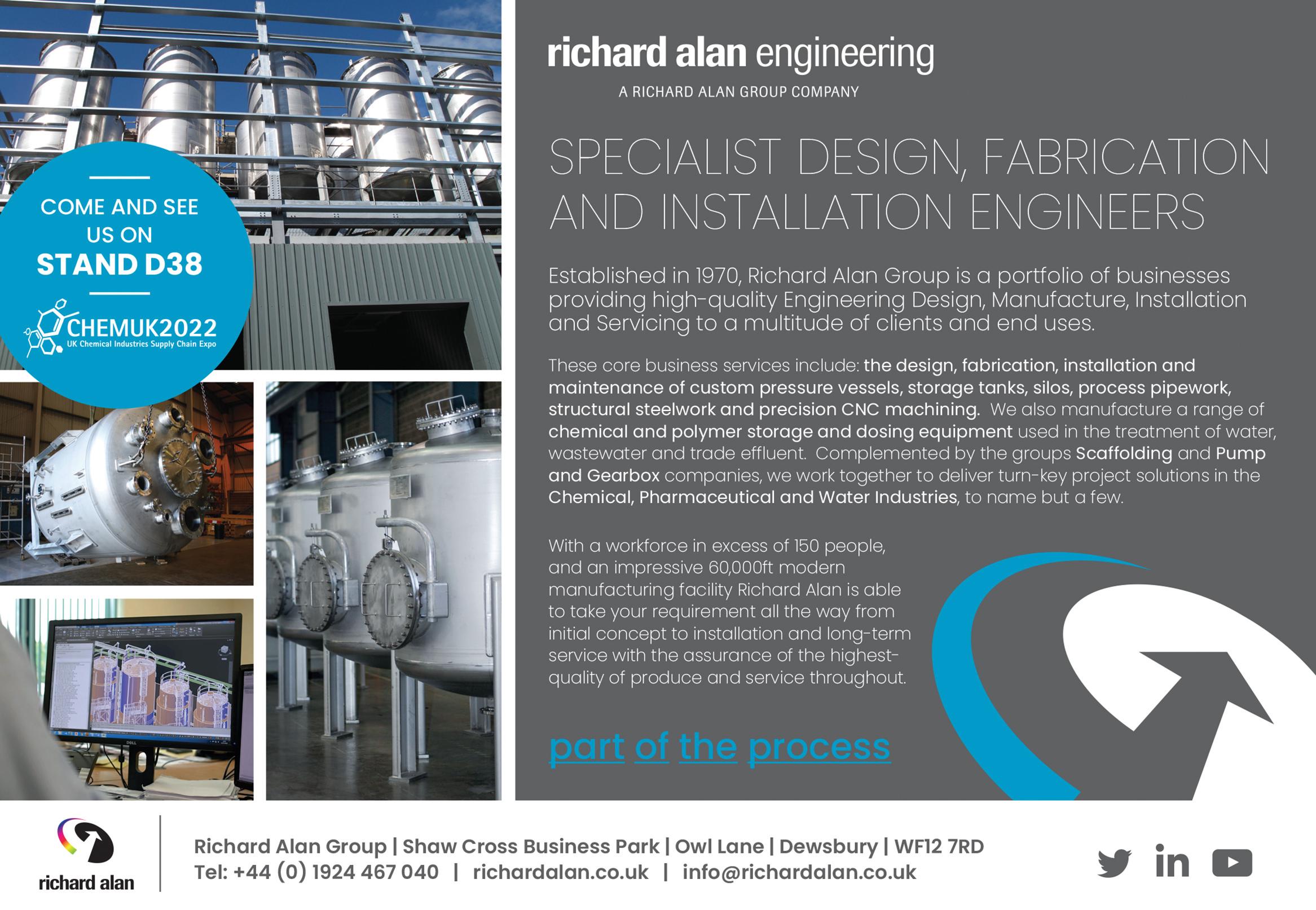

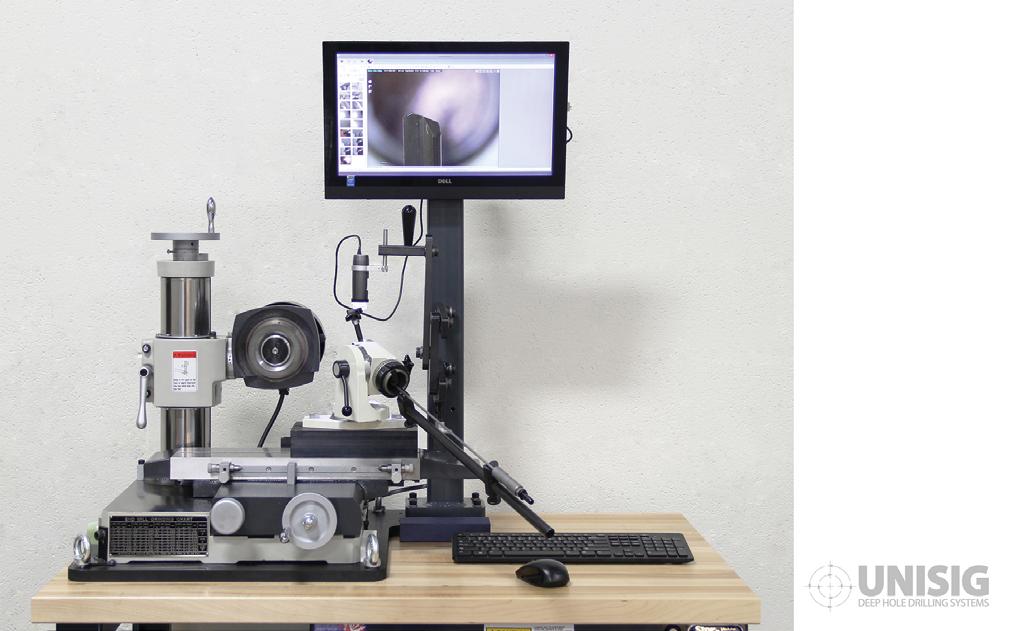

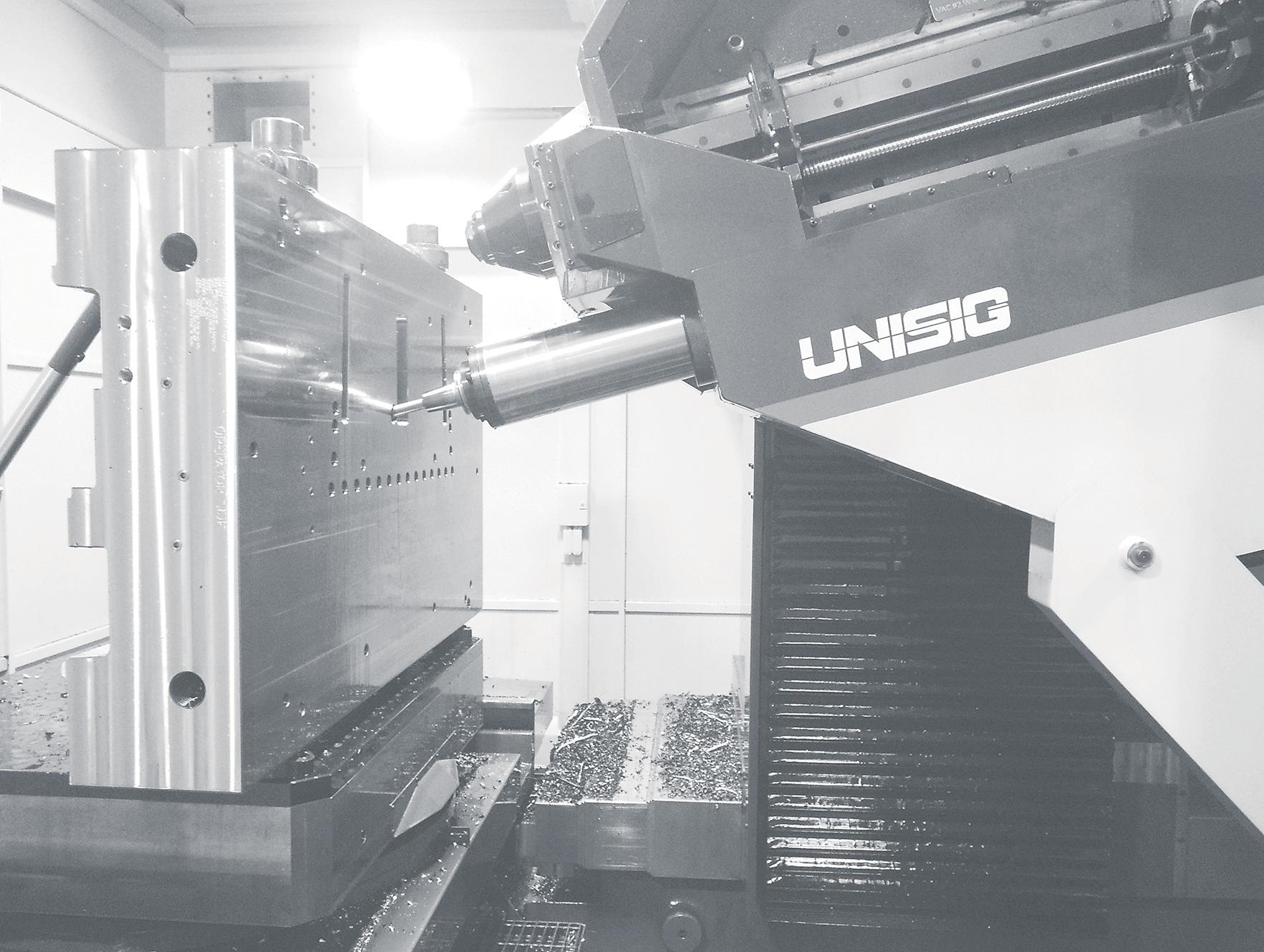

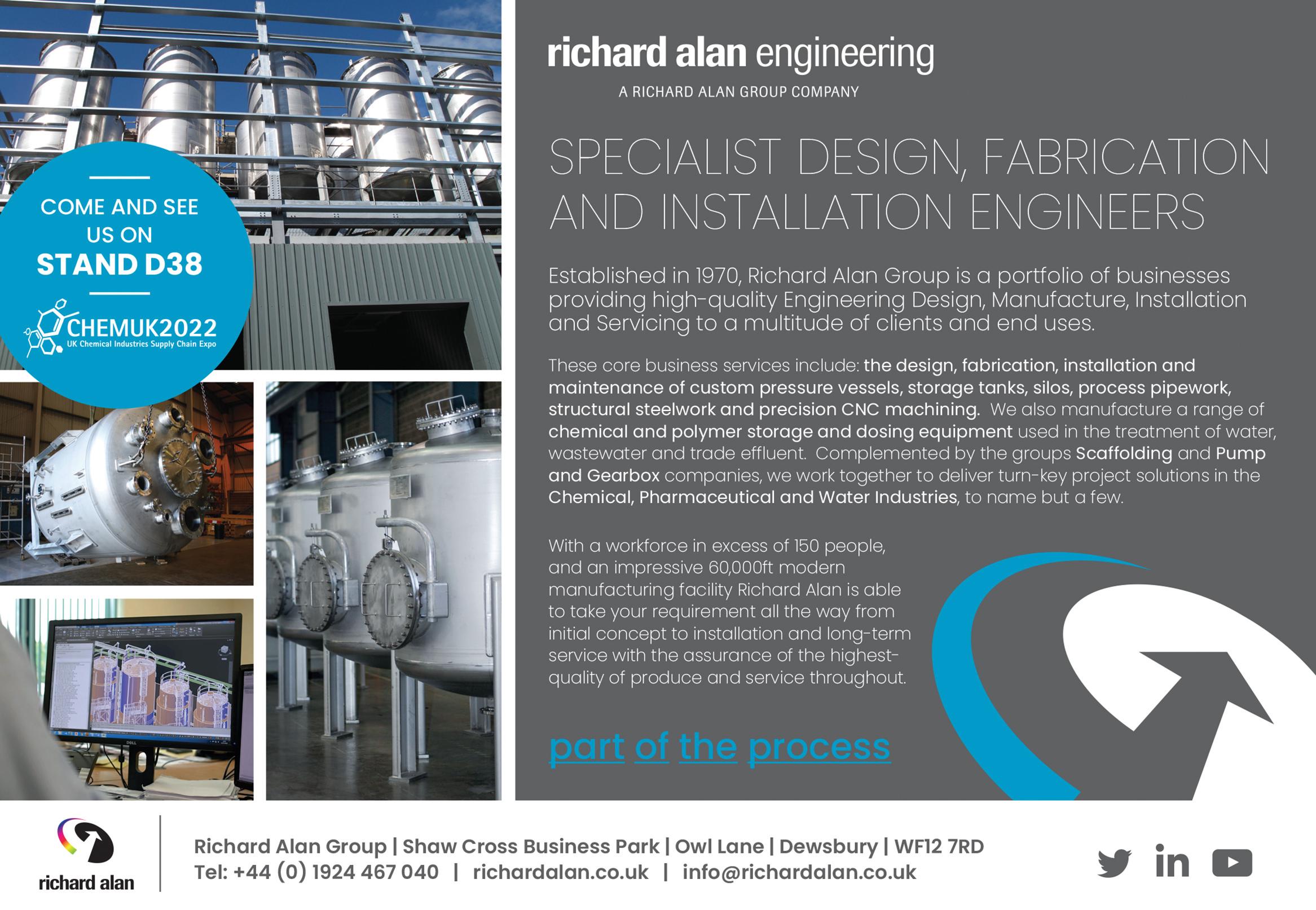

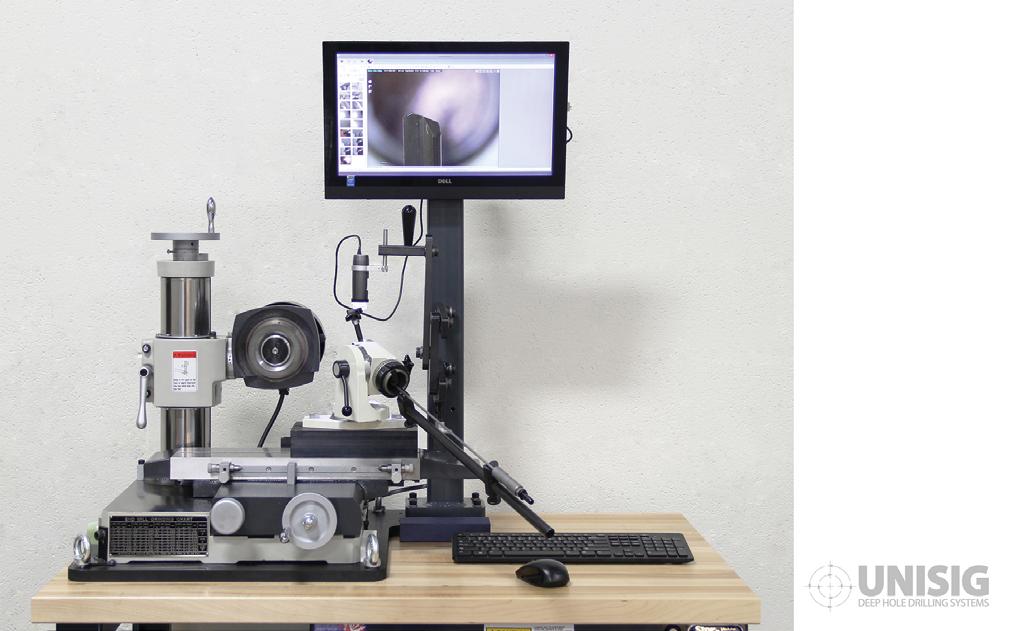

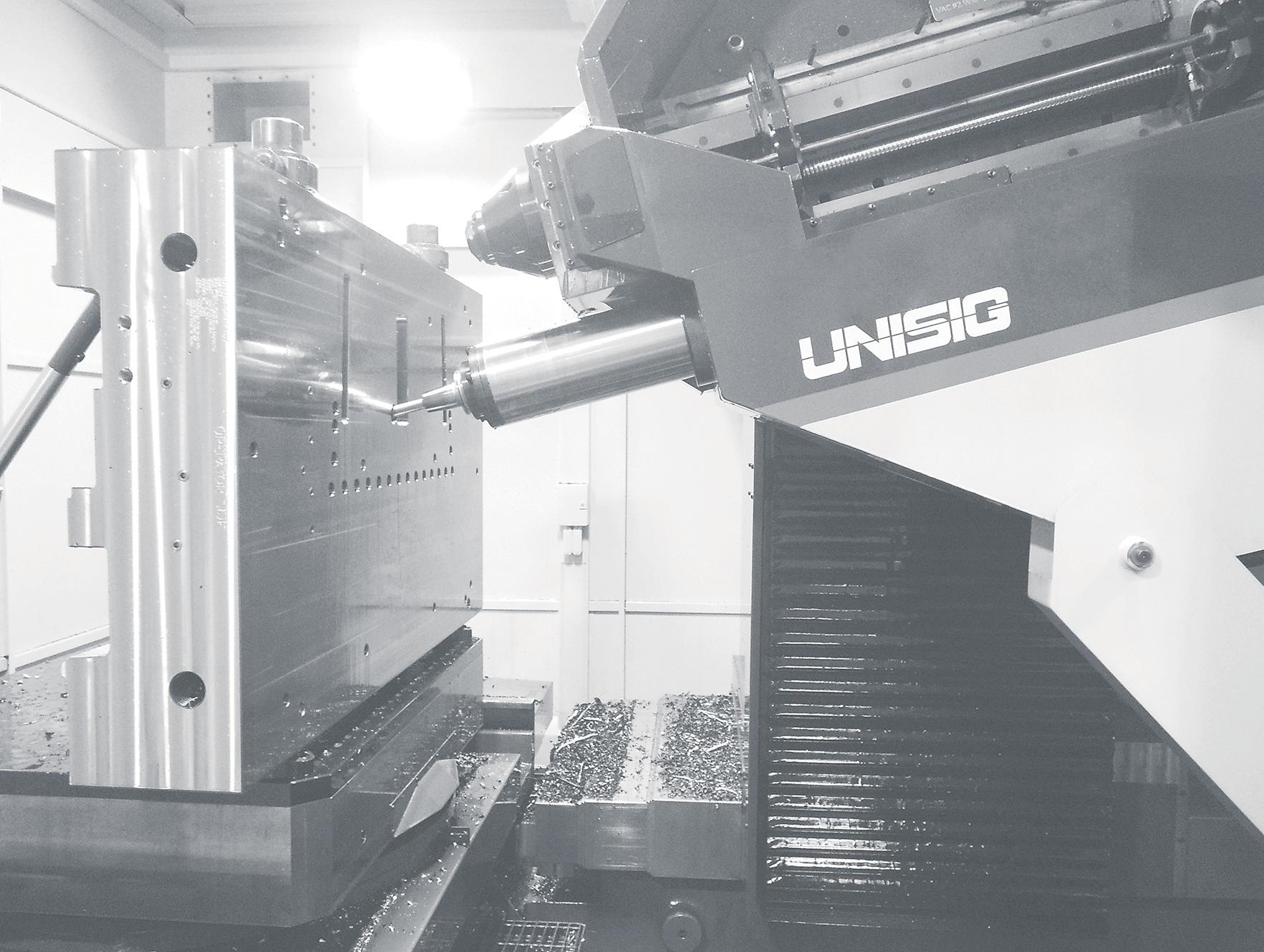

UNISIG DEEP HOLE DRILLING SYSTEMS: PERFECTION IS NEVER AN ACCIDENT

UNISIG produces deep hole drilling machines that are used around the world by nearly every industry imaginable – and at UNISIG, striving for perfection has never been an accident. To secure long-term success, the company decided to further invest in machining its own precision parts rather than subcontracting components, as some of the most critical parts they produced have tolerances and complexity that cannot be made by most machine shops.

To machine their own parts while continuing to grow and develop new products, UNISIG embarked on a new approach to machining which would allow for industry-leading CNC machine tool accuracy and performance to be coupled with new technology that would ultimately eliminate manual intervention in machining that prevails in many shops.

“The deliberate connection between engineering, design, and machining improves our product. Our ability to rely on very high accuracy and productivity from our internal machining capacity allows UNISIG to provide more advanced solutions and value to its customers,” quoted Anthony Fettig, CEO of UNISIG.

Automated machining was the goal, which required a change in thinking by the team’s engineers,

programmers, and machinists. To harness this new direction, UNISIG put in the time and energy to secure the best manufacturing resources available, including several Okuma machine tools.

To begin, UNISIG devised a plan to combine modular fixturing, offline tool setup, and full simulation of the machine, workpiece, and tools to provide a platform of innovation within their machine shop. The team’s intent was to radically improve spindle uptime and exploit the full potential of automated CNC machining, even when the batch size would be only one part.

The first step of the UNISIG strategy was to move away from classic CNC boring mills and adopt the higher productivity potential of CNC horizontal machining centres with twin pallets. After consulting with credible industry sources and leveraging their internal team’s knowledge, the MB-10000H horizontal machining centre from Okuma was selected for medium-sized, high-accuracy part machining.

One of the most important factors in this capital investment was the need to trust the machine accuracy enough to program from its centre of rotation and let the machine run without stopping and manually verifying the machining process many times during the cycle. The Okuma MB-10000H

Handling, Storage & Logistics Update

installation was a success and reinforced UNISIG’s wisdom to focus on automated machining – and the benefits were so extraordinary that UNISIG continued to look to additional Okuma solutions to bring its strategic vision to life.

UNISIG’s next target was large-part machining.

Previously, to hold the finished machine tolerances, extensive hand scraping was necessary which added a lot of time and expense to produce these machines. UNISIG established a set of machining accuracy parameters that would eliminate much of this handwork to achieve tolerances.

Working directly with the local distributor, Morris Midwest, UNISIG was able to engage with Okuma America and Okuma Corporation’s technical leadership to tailor the specification of an Okuma MCR-A5CII 35x10 double column machine for the exacting geometry and overall volumetric accuracy needed.

The collective Okuma team ensured the MCR-A5CII machine tool specifications were defined and perfect for UNISIG’s application. A quick-change fixture system was developed by UNISIG to allow two parts up to 3 m (10 ft) long to be machined simultaneously and removed for setup offline. The results after installation were very impressive,

allowing lights-out automatic machining of parts previously not possible for UNISIG to manufacture. With two machines from Okuma running and performing to expectations, one more opportunity identified for upgrade resulted in the new MA12500 machine. The OSP Control common to these three Okuma machines was a big value to the programming and simulation group at UNISIG. “This baseline trust in Okuma is what allows UNISIG to excel at advanced manufacturing,” said Mr. Fetting.

In addition to offline tool presetting and modular workholding on all machines, UNISIG uses a variety of Okuma’s Partners in THINC suppliers including: Mastercam, Vericut® and Renishaw. Using a layered approach to technology and understanding the benefits of eliminating the gaps between engineering, design, and manufacturing, UNISIG has differentiated itself as a machine tool builder. The company’s long history of achievement is one Okuma and Morris Midwest are proud to be a part of – especially in helping UNISIG achieve their goal of capitalising on the full potential of automated machining.

For more information, see below.

T +49 7125 9687590

www.unisig.com

Industry Update is sponsored by EyeC – see them on page 4 10

Test & Measurement Update

Environment, Health & Process Control Company of the Month

ECO PHYSICS, measurably better!

In this issue of Industry Update, we are pleased to announce ECO PHYSICS AG as our Environment, Health and Process Control Company of the Month.

Since 1989, ECO PHYSICS AG has had a passion for innovation. On a mission to contribute its know-how and technology to environmental preservation, human health and industrial innovation, the company believes fulfilling a social responsibility is just as important as economic achievements.

ECO PHSICS AG is committed to offering innovative analytical solutions for measurement tasks in the field of environment, health and process control. With an ECOlogical leadership, the company is dedicated to sustaining the environment through its business activities. Dr. Grischa Peter Feuersänger, PhD, Head of Sales & Marketing explained the role of the company in more detail, “next to carbon oxides, the reduction of nitrogen oxides in our atmosphere is the decisive factor to diminish the ozone appearance on ground level and the greenhouse effect in the stratosphere. With this in mind, we offer innovative analytical solutions for measurement of nitrogen oxides and related gas components like ammonia, in the fields of environment, health and process control. With our interdisciplinary research and development team we deliver customer oriented, tailor-made products and services.”

Headquartered in Dürnten, Switzerland, ECO PHYSICS AG also has one office in Germany and one in the United States and is present throughout the world. As a supplier of gas component

detector technology, ECO PHYSICS AG’s products provide many benefits for the industry.

ECO PHYSICS AG offers a broad range of nitrogen oxide analysers for fast and precise nitrogen oxide monitoring in various fields of applications. Following a product portfolio update in 2020,

the latest nCLD series by ECO PHYSICS AG uses a new graphical 7-inch coloured touch screen by which the instrument is locally operated from, with each NOx analyser capable of measuring various parameters combined with high adaptability to a multitude of sampling conditions. The range includes nCLD Economical Line, nCLD Modular Line, nCLD Supreme Line, and nCLD Ambient Line.

Dr. Grischa Peter Feuersänger explained: “Our analysers contain the widest variety of instruments and application types, measuring from 10,000 ppm down to 1 ppt (part per trillion). Besides the wide application coverage, each instrument also has remote operation and service access capabilities.” Suitable for use in automotive, medical, industrial, semiconductor, environmental, ambient air and research applications, analysers from ECO PHYSICS AG are marked as the industry’s finest.

“The graphical user interface enables a simple operation and shows the performance of each component. They are all equipped with their own PCB, corresponding with the mainframe. This status can be remotely accessed. Therefore, a detailed diagnosis can be made before any service intervention is conducted. The modular design and the individual, intelligent components make us a market leading brand,” continued Dr. Grischa Peter Feuersänger.

This past year has provided its share of challenges for many companies, but ECO PHYSICS AG has also taken this time to find new opportunities. “Yes, public funded projects were delayed because the public sectors like research, universities, governmental and local authorities did not receive funding in 2020 or 2021. However, due to the portfolio updates we have received a growing number of customers in the industrial sector.

In 2021, we welcomed our new CEO Mr. Dirk Wendt, and we are currently excited about the expansion of our R&D personnel for new developments,” stated Dr. Grischa Peter Feuersänger.

For more information, see below.

T +41 55 220 22 22 info@ecophysics.com www.ecophysics.com

Pumps & Valves Update

Industry Update is sponsored by ECO PHYSICS AG – see them on page 11 11

Heating, Ventilation & Air Conditioning Update

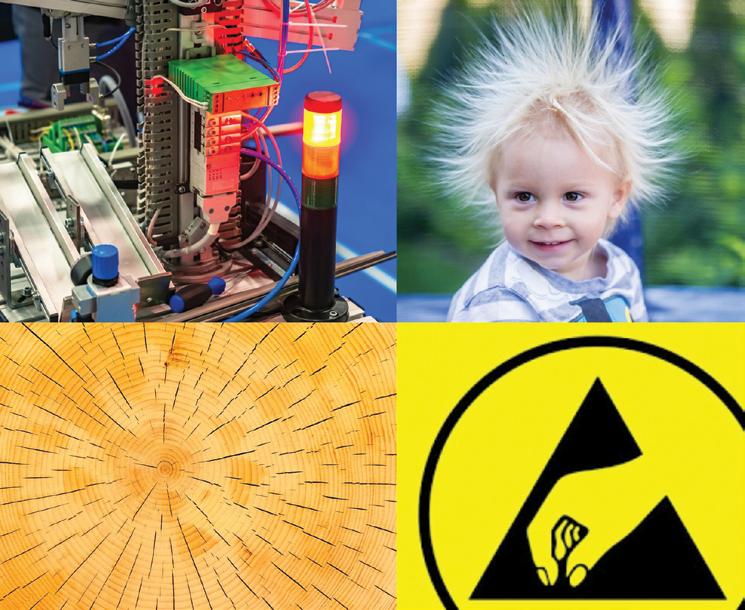

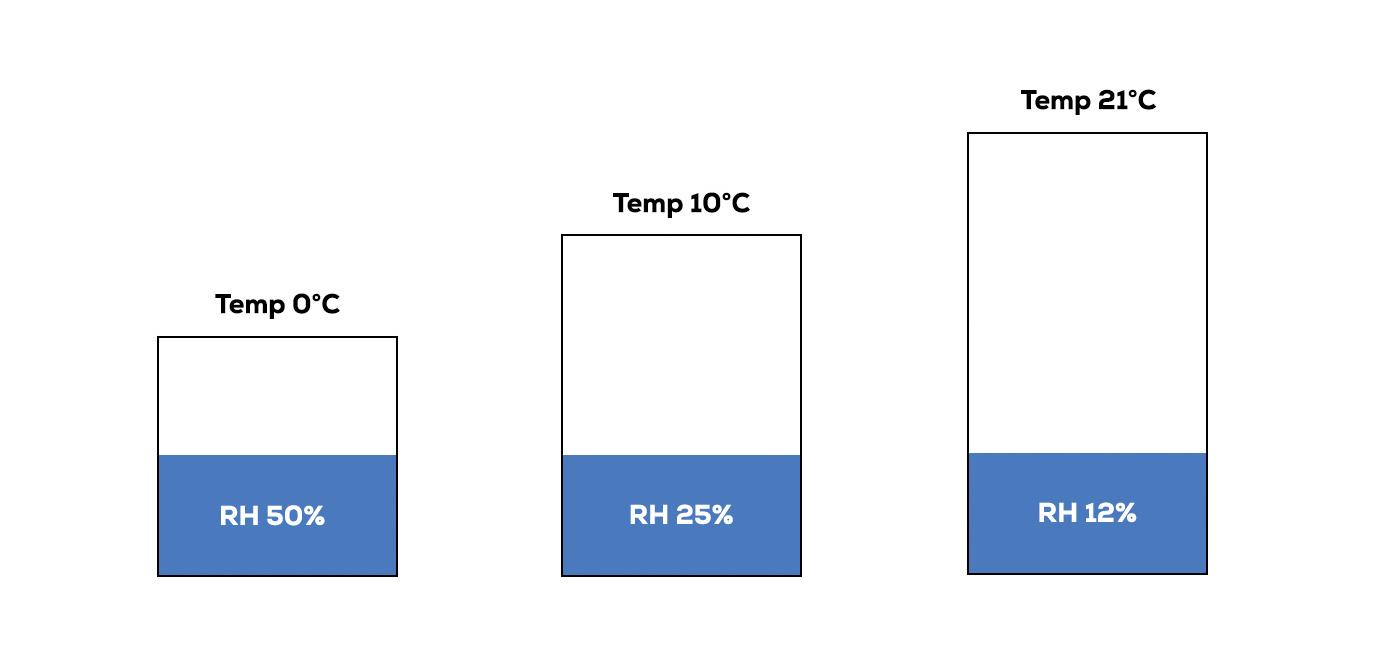

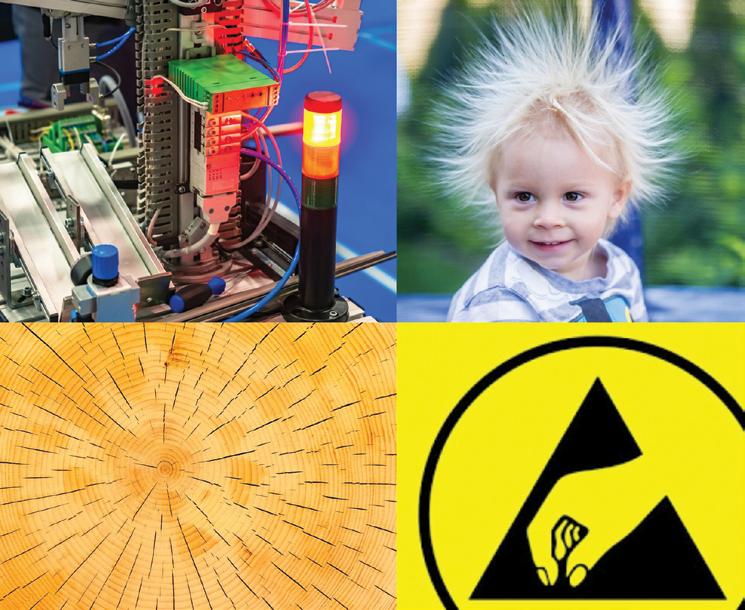

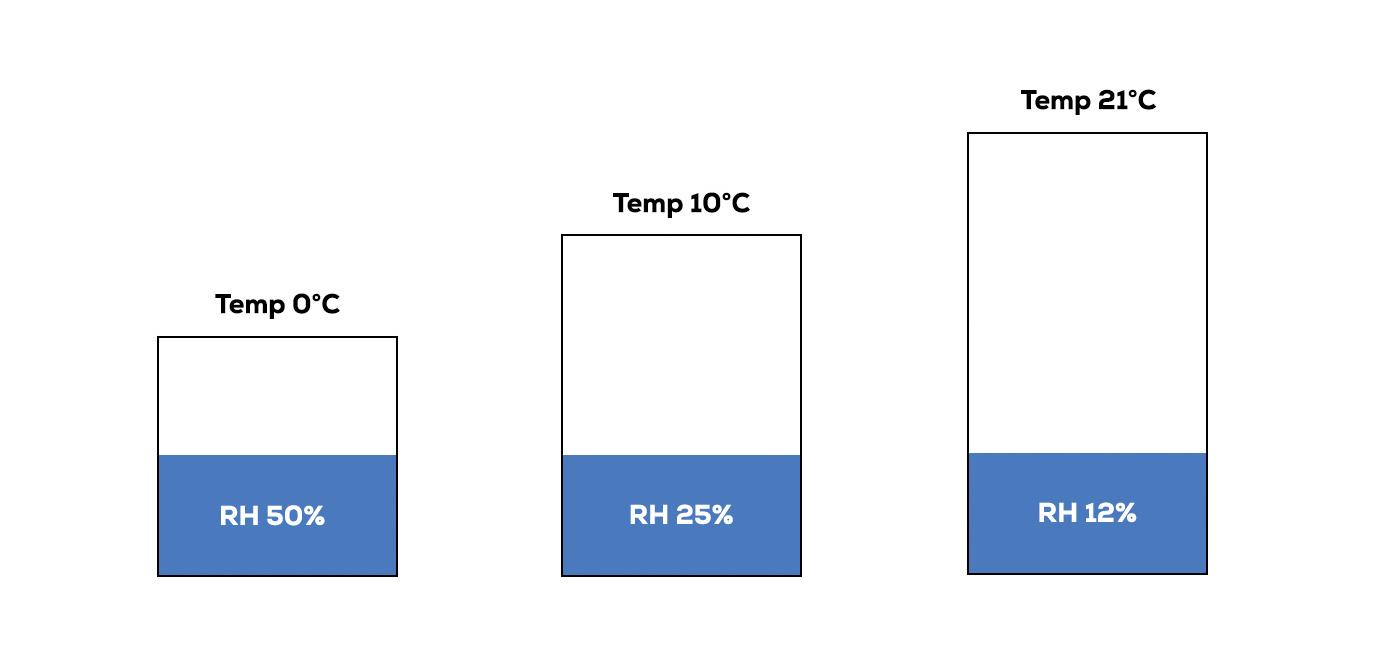

Humidity in the winter

Humidity levels drop in the winter because cold air holds less moisture than warm air. Many large buildings, warehouses and factories use air handling units to ventilate and heat large areas. These units take the cold dry air from outside and convert it to warm air inside. The problem gets worse when the dry air heats as it loses even more moisture, resulting in lower relative humidity.

human well-being and mechanical performance. Read more to find out how low humidity effects both human and mechanical production.

How does low humidity effect our wellbeing?

Low indoor relative humidity has a negative effect on human comfort. The adult human body is typically 60% water, so in a dry environment our bodies naturally lose moisture. Unlike temperature, low humidity is more difficult to detect.

The Science Relative humidity is the amount of water vapour actually in the air, expressed as a percentage of the maximum amount of water vapour the air can hold at the same temperature.

At any given moment an air molecule will hold a certain amount of moisture – more on rainy days than hot sunny days. In winter, cold outside air (whether ‘wet’ or ‘dry’) is brought inside and heated. As air heats it expands, but the actual moisture content of each molecule cannot change, and therefore the relative humidity falls.

It is widely acknowledged that maintaining relative humidity levels between 40-60% significantly improves

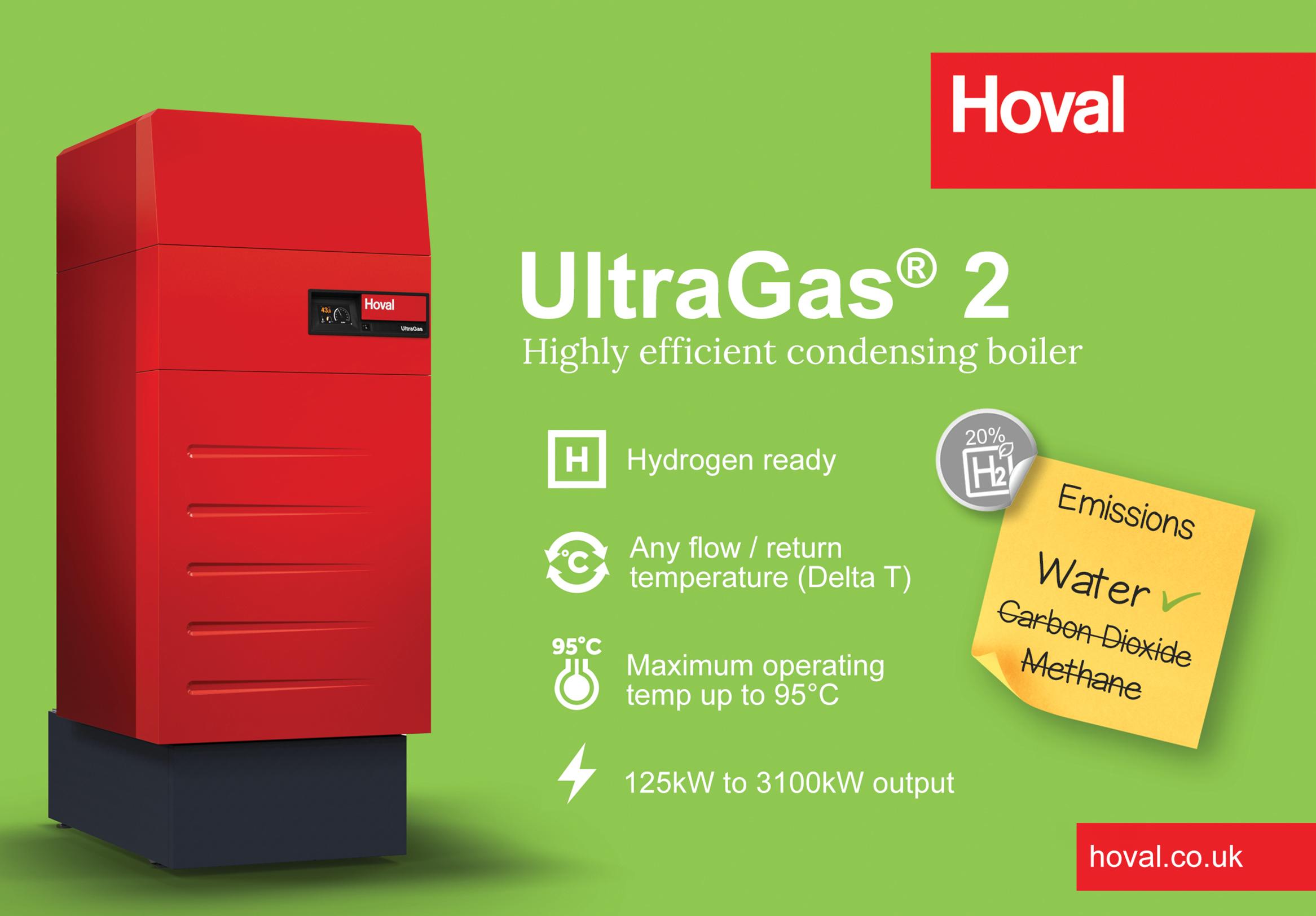

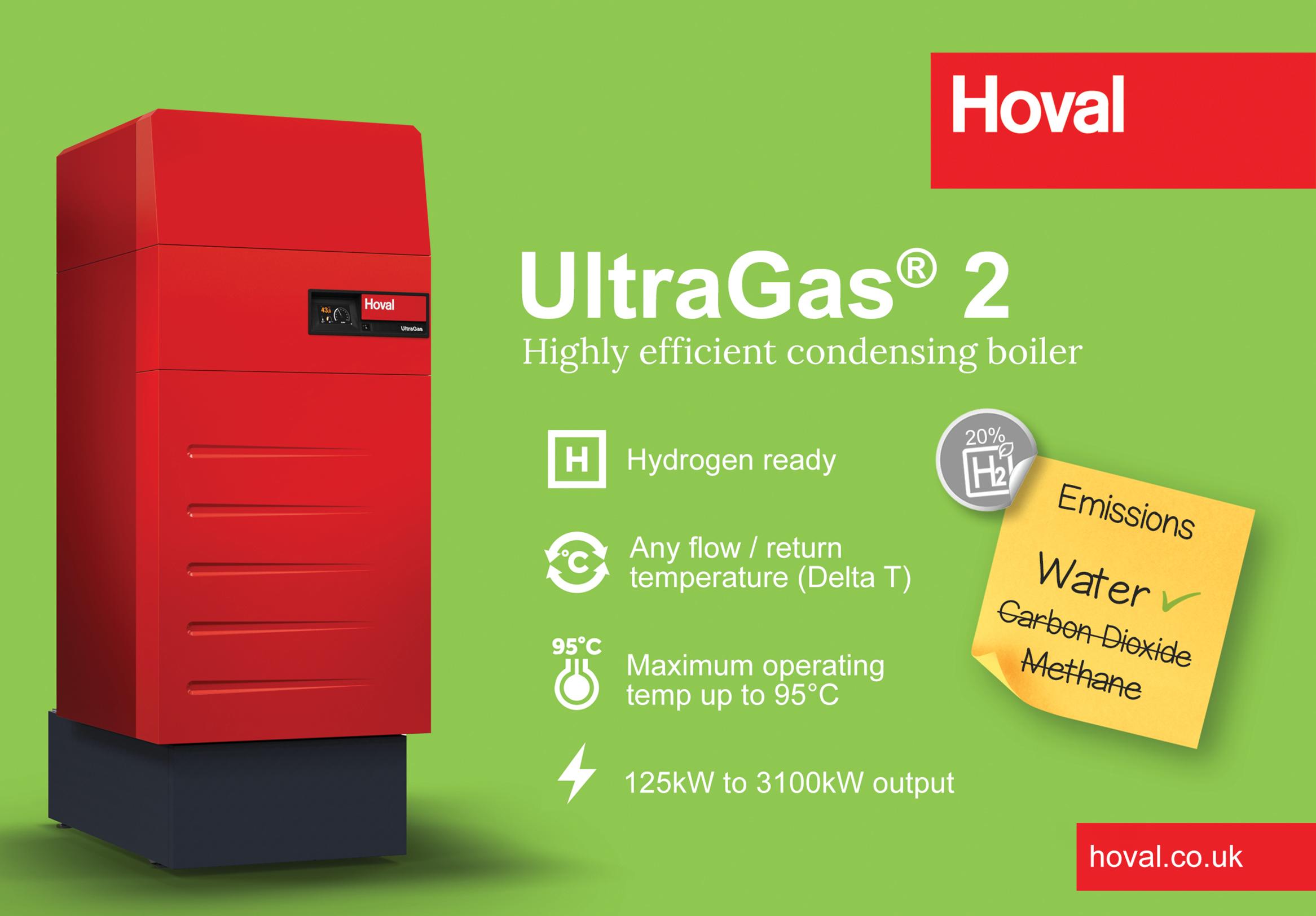

Hoval’s UltraGas 2 is ‘hydrogen-ready’

Typical symptoms include:

t Dry and itchy skin

t Cracked lips

t Dry eyes (especially for those with contact lens)

t Sore throats

t Nosebleeds

t Headaches

In addition, low relative humidity dries our mucous membranes and inhibits our body’s natural defence against germs, viruses, and bacteria, making us much more vulnerable to catching common colds and flus.

Maintaining relative humidity between 40-60% is scientifically proven to reduce the spread of airborne pollutants and viruses.

How does low humidity effect mechanical processes?

Moisture absorption also affects hygroscopic materials like wood and paper. The low humidity dries out these materials causing them to shrink, curl, crack or split. When these materials pass through machines, usually at high speeds, it causes paper jams and machine breakdowns. A list of common problems is listed below.

t Static electricity build-up and ESD

t Drying out of hygroscopic materials like wood and paper

t Paper jams and machine breakdowns

t Increased wastage

t Decreased productivity

The Solution

There is a wide range of humidifiers and a variety of factors to consider in selecting the right humidifier for each building or application, such as energy use, water supply, cold water or steam, gas or electric, evaporative

or spray, humidifier situation, control compatibility and maintenance needs. It is therefore important to seek advice from specialists who can provide guidance and design a bespoke system that will serve each unique specification. Installation, commissioning, spare parts, ongoing service and maintenance costs also need to be considered, and a planned maintenance contract is recommended to ensure equipment is kept in good working order and the initial investment is not wasted.

Humidity Solutions have a team of experienced and highly knowledgeable engineers who can advise on a full range of applications and provide a complete turnkey solution, providing reassurance for the customer and protecting their investment in both their people and their machinery.

T 01372 571200 info@humiditysolutions.co.uk www.humiditysolutions.co.uk

Industry Update is sponsored by EyeC – see them on page 4 12

The UltraGas® 2 range, Hoval’s latest generation of gas condensing boilers, offers the option of using hydrogen as an alternative fuel to natural gas to deliver zero carbon emissions. Moreover, gas-fired models that are installed now can easily be converted to hydrogen in the future. UltraGas® 2 is also compatible with biomethane. Thanks to the standardised Hoval TopTronic® E controller, UltraGas® 2 boilers can be easily combined with any type of heat generator and solar energy system to create hybrid systems that deliver optimum efficiency with minimal emissions. With a maximum operating temperature of 95Deg.C they are ideal for use in district heating/heat networks. Efficiency is also inherent in the UltraGas® 2 design. For instance, the patented Hoval TurboFer® heat exchanger uses injection technology to generate turbulence and boost efficiency, while high and low temperature return flow, a large water capacity and the Ultraclean® combustion system combine to deliver unparalleled performance. UltraGas® 2 models are available with output ratings from 125kW to 1550kW (250kW to 3,100kW as a double boiler), and in 10 bar versions for 720, 1100 and 1550kW units. Ease of installation has been a key element in the design, so there is no need for system components such as a circulating pump or hydraulic separator. The amount of pipework in the TurboFer® heat exchangers has also been reduced to minimise weight, resulting in a lightweight, compact design. www.hoval.co.uk

Sustainable recycling solutions

In this issue of Industry Update, we have selected Presona UK as our Water, Energy & Environmental Company of the Month.

Established in 2008, in just 13 years Presona UK has grown to be one of the world’s leading manufacturers of baling equipment. Founded with a vision to make recycling easier and more efficient for its customers, Presona has morphed into an establishment to which its employees and customers still remain at the core of its ethos.

With its main head office based in Tomelilla, Sweden known as Presona AB, Presona UK is able to draw upon its resources and synergies from the global presence Presona has established. From customer service to technical expertise, Presona has been essential in supporting and raising the consistent standard of efficiency and professionalism within the recycling industry. One of the most important areas in which Presona’s experience helps to deliver innovative products and services designed to save customers time and money is through the development of its balers, conveyors and waste extraction systems, all of which are designed to meet these objectives. Furthermore, Presona equally works to reduce stress within the recycling environment by identifying and resolving pinch points and providing operator training, comprehensive preventative maintenance programmes and a 24/7 support whenever needed.

Presona work within many industries, whether you’re a recycler, logistics company, manufacturer or retailer, Presona has a goal to improve all companies recycling performance. Recruiting many highly skilled staff with advanced technological and industry knowledge has built the backbone of which enables Presona to develop excellent products and services. Its team of compassionate, friendly, and professional people are on hand to design, install and maintain all Presona products and services ensuring maximum efficiency and efficacy with minimum stress.

As a solution-based company, Presona only sell a product or service to a customer if it can make a positive benefit, thus being to improve time management, profits and smooth out operations. Presona only produce the highest quality recycling process equipment that are designed with the latest and most effective technology and methods available.

Presona produce its own range of balers that are some of the most efficient balers on the market with some savings of up to 60% on conventional shear balers. “We supply our own range of baling equipment capable of producing anything from 40 tonnes of pressure right up to 270 tonnes. Our balers will process a range of recycling materials like paper, cardboard, plastic and some metals, into dense bales for easier, more costeffective shipping. Other benefits include time, team

and money, meaning that our balers and equipment will give more time to our customers and time to focus on other areas of their business. Our equipment will make their team more effective at their job due to less manual intervention from staff on our fully automatic equipment. With the mixture of saving customers time and giving their team other areas to work on, this will in turn save them money on expenses within their business,” stated Richard Portas, Customer Accounts and Marketing Manager.

Presona offer a range of balers that can be used to compact materials such as municipal and solid waste, packaging materials, textiles, carpets, metals, RDF and SRF and more. There is also a series of fully automatic LP Range balers for larger, heavy-duty applications throughputs.

Its latest invention the MP 270 MH ‘Mega’, is a baler designed to reduce multi baler sites down to the need for just one baler. Its capable of producing 270 tonnes of

pressure giving exceptionally dense bales of cardboard, plastic and paper, and up to 45 tonnes per hour.

Chain belt conveyors are an integral part of recycling and waste management plants. Presona has a rich history of designing and supplying bespoke conveyor systems to support its LP series balers. The PreVaya is Presona’s latest conveyor system which is better suited to rugged environments and easier to maintain and upgrade than any others on the market.

The PreVaya can be used with any make of baler and can be tailored to individual requirements, material and footprints. Designed to solve recycling/waste problems by including high side walls and a system to accommodate exceptional tonnages, it’s heavy-duty, galvanised inside and out and servicefriendly. “The PreVaya is modular construction that saves on downtime as there is no need for specialist tools like cutters and welders, it’s a simple case of unbolting, replacing, check and leave,” said Richard.

In 2020, Presona helped ethical retailer Co-op further reduce its carbon footprint with the installation of two new balers and Presona built conveyors at the firms Avonmouth and Andover Distribution Centres. The

Co-op group used the balers to compact the recovered store materials for recycling and reuse into new films and boxes. The production of materials compacted through the balers supported the Co-op in reducing the number of lorry movements in moving materials to recycling centres and mills around the UK. The partnership was a glowing success to which Co-op stated its wishes to continue working with Presona more in the future.

In further support to the recycling industry, Presona can design, build and install custom, cost effective materials recycling sorting plants. A typical plant can be designed for two or more fractions with an annual material flow of between 30,000 to 300,000 tonnes. From start to finish, Presona take complete responsibility for the contract, project planning, design, erection, commissioning and ongoing maintenance of the plant.

Some production processes can result in lots of small material offcuts where a manual collection system can be inefficient. Presona create bespoke waste extraction systems to combat this issue. Its designers will create a system with the optimum air and material flow capacity via the most effective number of suction points whilst minimising energy consumption. These can be used as a standalone plant or can be seamlessly integrated with Presona balers and conveyors for an unparalleled system.

Presona’s products and services provide critical benefits to its customers thanks to its carefully thought-out innovations and extensive technical know-how. Its products and services allow customers to be more productive with their time and expenses that would once have been lost through unnecessary and inefficient recycling processes.

Delivering a structured, fair and consistent service, Presona’s products offer a solution that has been tried and tested for many years. Taking ownership to constantly improve, allowing no room for complacency, Presona is always pushing the boundaries of innovation to make further solutions for better recycling processes.

For more information, see below.

T 01278 444527

sales@presona.co.uk

www.presona.co.uk

Industry Update is sponsored by ECO PHYSICS AG – see them on page 11 13 Water, Energy & Environmental Company of the Month

Industry Update is sponsored by EyeC – see them on page 4 14 Environmental Update

Setting the standards for the sewage industry

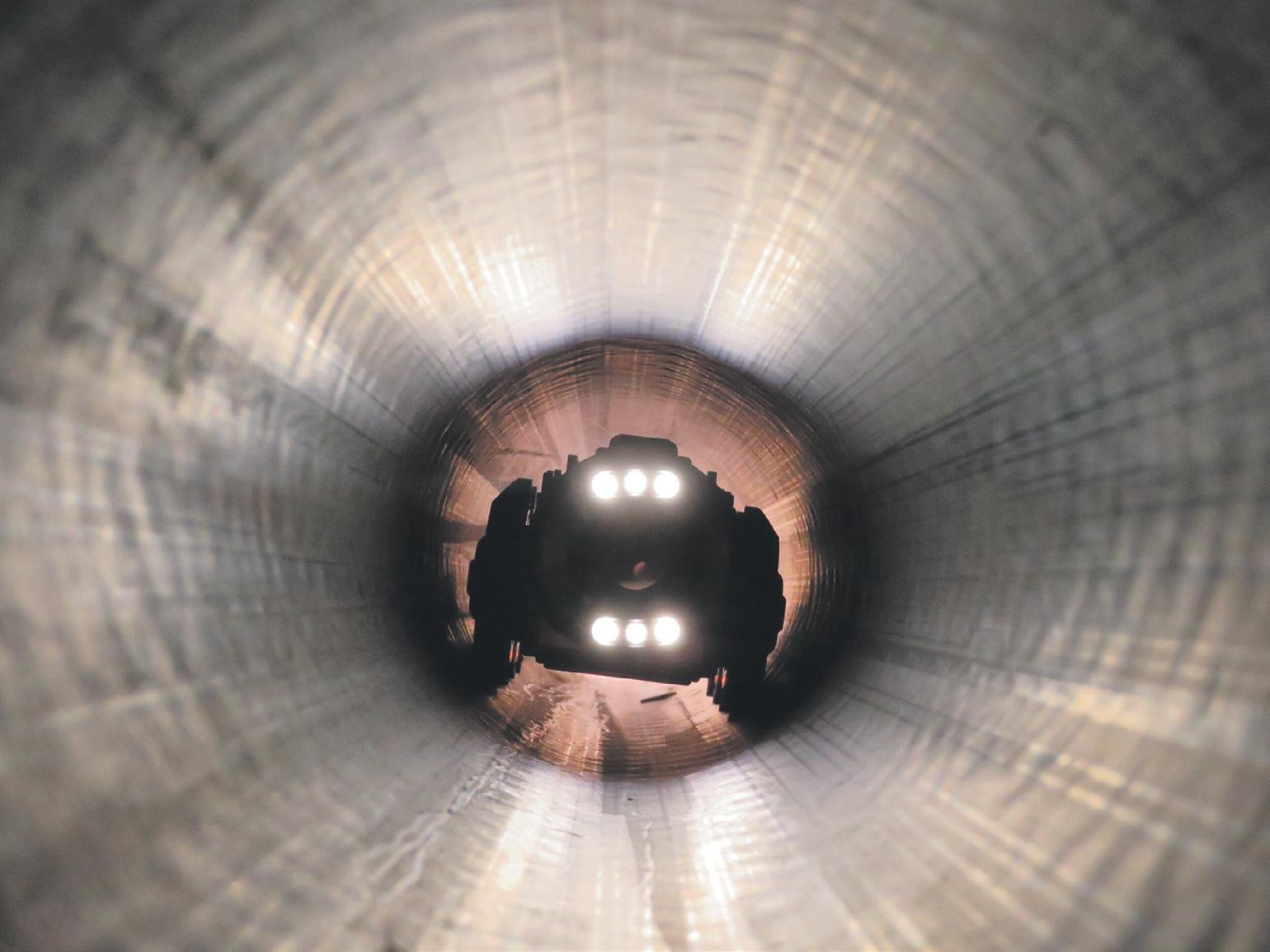

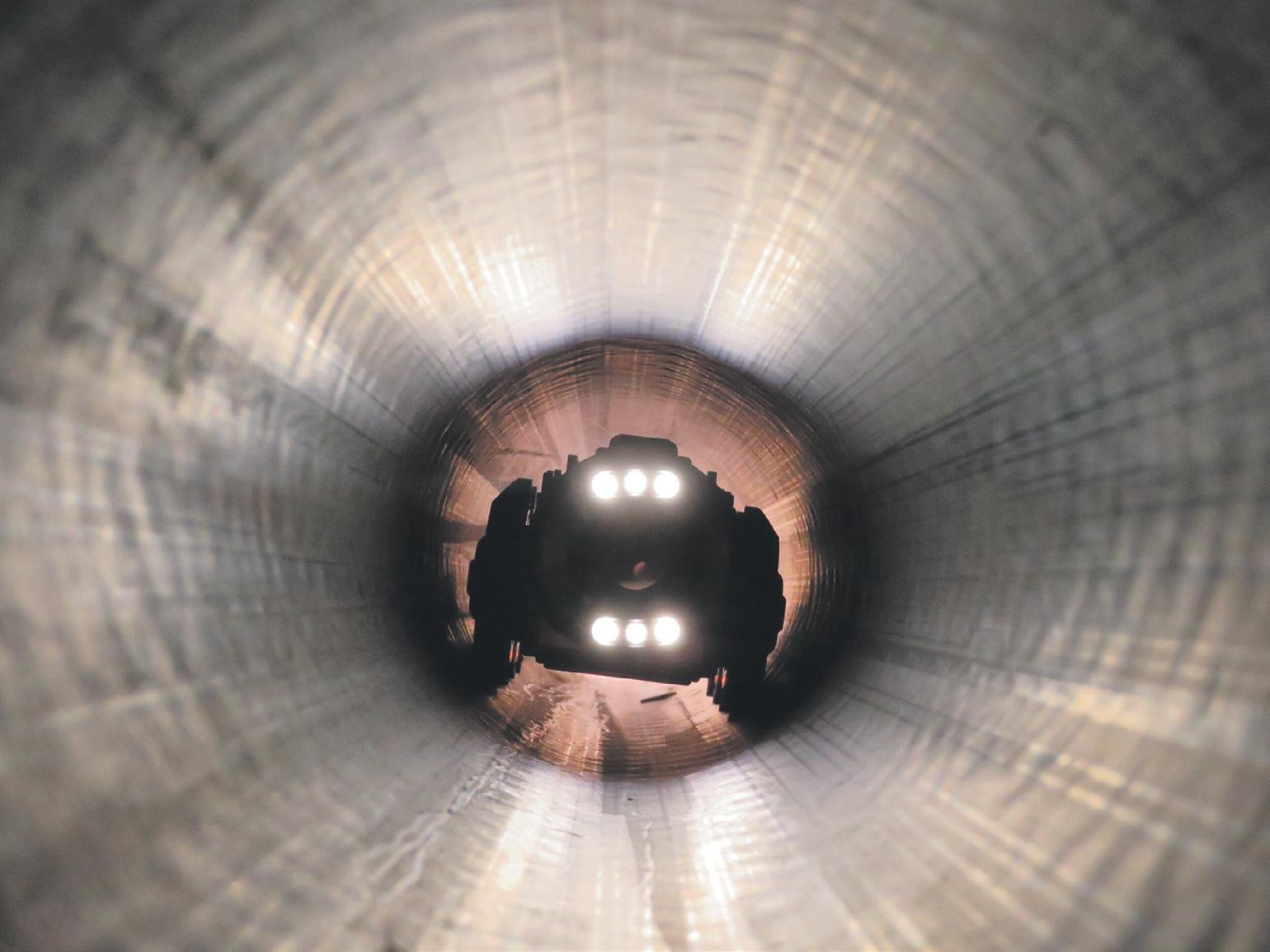

In this issue of Industry Update, we are proud to announce that we have selected The National Sewerage Association (NSA) as the recipient of our Association of the Year Award. NSA has built a strong reputation through its credentials within the sewerage industry and the association was formed in 1996 to represent the interests of companies associated with the survey, operation, maintenance and renovation of sewers, drains and pipelines.

“The National Sewerage Association has its roots in the Association of CCTV Surveyors which was founded in 1980 when a number of smaller contractors wanted a voice in the industry which was then dominated two larger companies. Some three years later the Association of Flow Survey Contractors was formed. Some five or so years

later, as the majority of members belonged to both, the two Associations merged to form the National Sewerage Association,” stated Val Gibbens, Secretary.

The NSA represents the interests of companies connected with the survey, operation, maintenance and renovation of sewers, drains and pipelines. The Association maintains representatives on several standards committees and communicates with other trade bodies on subjects of shared interest.

NSA acts as a forum for its members, providing a platform to ensure that technological developments and improved operational efficiency are achieved

and helps to ensure that its members meet the ever expanding, service standard requirements. In addition, the Association is dedicated to identifying customers’ needs, service standards and performance criteria for its members, alongside looking at existing and new market opportunities.

NSA also acts as a focus for complaints on nonconformance and other general or technical inquiries.

Val added, “The Association provides an arbitration service for the members and runs occasional audits to ensure standards are being maintained. The audit service is valued by many of the members. Any technical queries are responded to and where the answers are not available in-house, solutions are sourced elsewhere.”

The focus of the NSA, has been concentrated on standards and good working practices; thereby providing its members with the sound foundation to work to the contractual requirements of the Water Authorities/Companies.

“We look to ensuring that revision to standards and working practices continue in fairness to all parties and areas of conflict are avoided with a watching brief on equipment and reporting evolution,” said Val.

The Association holds high expectations for its members, especially in regards to meeting high criteria for staff training, in the tough environments in which they operate. This includes reporting procedures for sewer and drain inspections, flow survey analysis, confined space entry, lighting, signing and coning, water jetting and workplace awareness.

The Association and its officers are recognised for their depth of knowledge within the sewerage maintenance industry, being approached by external bodies as needs determine. In fact, the NSA has been involved in the preparation of National Contract Documents as well as standard operating and reporting systems.

Proud to be regarded as an industry standard setter, the NSA have been actively involved in the

development of various standards including the development of European Standards for Pipe Defect Classification, the result being the publication of BS 13508:2 in 2003 with implementation of the National Equivalent in 2008 and its successor.

In addition, the operative standards have been set and in conjunction with Develop Solutions (previously WTi), team leaders and operatives receive efficient training and accreditation, to meet the standards required by the Water Services Plcs.

Training standards have also been developed for sewer jetting and cleaning, to meet new codes of practice and a basics skills course has been put in place for personnel operating in the domestic market, enabling them to obtain City and Guilds Certification.

“Particular efforts are made to increase awareness of the Association, its aims and services among relevant client groups, regulation bodies, professional bodies, Government departments and contact groups and training bodies,” mentioned Val.

The Association is also responsible for the

accreditation of its members and places a strong focus on policing and monitoring their performance for customers.

In terms of recent developments, as the industry constantly evolves, so does technology, which has been a focus for the association.

“Computerisation of CCTV reports was just being introduced as the Association was formed and now, 40 years later, the coding system for computer input has progressed to a European standard (BS EN 13508:2). Surveying with AI is now very much under discussion and the equipment used within the industry has also evolved through the years with safety and improvement in electronics such as miniaturisation and lighting.

Val continued on other recent developments, “The Manual of Sewer Defect Classification, the Surveyor’s `bible’, is currently being updated in preparation for a 6th Edition. The Water Companies now expect certification to the 5th Edition to be held by operators working on their contracts; this now requiring a five year renewal. Standards are also in place for Flow Surveying, Mapping and Water Jetting with associated model contract documents.”

There have been many new challenges presented for the industry due to the COVID-19 pandemic. The period has provided some difficulty for NSA members with staff shortages and associated COVID-19 restrictions. Fortunately, as an essential service, NSA was able to carry on its operations during the pandemic and responded to new challenges by adapting to virtual meetings and working from home and has even noticed the benefits that home working has offered.

Val explained, “The last 12 months have seen no face to face meetings and talks etc. have been held via video conferencing. It is likely that this practice will continue, at least in part, as it allows greater participation and is more economic as travel time is saved as well as hotel costs.”

As the Association looks toward the future, it plans to continue to encourage maintenance of standards and good working practices by its members and the expectation of such from clients including the contractual quality control procedures. Val added, “We will also maintain a dialogue so that any new requirements/working practices are practical and to the benefit of all parties.”

Indeed, the NSA plans to maintain and grow with its industry, and to continue providing the best services, training and industry information for its members.

If you would like to find out any further information, please see the details below

T 020 8330 0123 www.sewerage.org

Industry Update is sponsored by ECO PHYSICS AG – see them on page 11 15 Association of the Year

Health & Safety Update

Fristads Green High Visibility

Fristads takes the next step in becoming a more sustainable supplier of workwear by launching its most comprehensive sustainably produced workwear collection to date – Fristads Green High Visibility.

The Fristads Green High Visibility collection consists of a wide range of garments making it possible for professional workers within many market sectors to dress from top to toe in high visibility garments with lower environmental impact – without compromising on safety and quality.

Leading the way in sustainability Fristads has a long-term goal to lead the workwear industry when it comes to sustainability and broke new ground when it launched the world’s first environmentally declared clothing collection Fristads Green in 2019. All Fristads Green products have an Environmental Product Declaration, an EPD, showing the garment’s total impact on the environment, from construction and material choices to waste and transports.

This is the fourth Fristads Green collection to be released. Since the launch of the first environmentally declared collection for craftsmen, the Fristads Green concept has been expanded to include garments for service and industry as well as outer garments. The plan is to offer environmentally declared Fristads Green garments in all product segments.

You can now calculate the environmental impact of your workwear using the GREEN calculator –www.fristads.com/en-gb/fristads-green-calculator

Contact Rob Freeman T 0203 026 7767 Sales.uk@fristads.com

The EL-WEM, EasyLog’s new WiFi Indoor Air Quality Monitor

Easy

Reducing cut risks

Since its formation in 1993, The Safety Knife Company has become a leading manufacturer of safer cutting tools and has helped to prevent countless workplace injuries.

The company’s original product, The Fish 200 Safety Knife, was the result of a chance conversation between the inventor, Bill Ireland MBE, and a farmer who had lost the sight in one eye after an accident cutting string on a hay bale. Once in production, the ‘Fish Knife’ soon found an industrial market as a safer alternative to an open blade knife for removing packaging materials.

Over time the range of products has gradually grown to include other ‘enclosed blade’ safety knives and a variety

of retractable blade knives. We are also a stockist for the innovative Slice ceramic blade cutters.

Most of our products are available in ‘metal detectable’ plastics making them suitable for use in food production areas.

We are regularly asked to solve specific problems by customers. Recent project examples include mounting a safety knife on a telescopic pole to enable operators to cut strapping from building materials on lorry trailers. This does away with the need to climb on to the trailer and therefore be ‘working at height’.

NOVA Safety Knives. We are delighted to have been

appointed as exclusive distributor for the UK and Ireland for the NOVA Safety Knife range in early 2021.

Our products are available from our web shop, through 100’s of distributors or directly from our sales office. We also have experienced staff on hand to help you through the evaluation process if you are looking to introduce safety knives to your workplace.

T +44 (0)1452 887900

enquiries@safetyknife.net

www.safetyknife.net

When

configured to send notifications of poor air quality by email and SMS messages. You can also view, analyse and download your measured data.

View and purchase the EL-WEM here and keep an eye out for the rest of the EL-WEM range coming out soon.

Your data, anytime, anywhere.

www.lascarelectronics.co

Industry Update is sponsored by EyeC – see them on page 4 16

Designed to help ensure high levels of air quality at work and in the home. Measuring particulate matter, VOCs, temperature, humidity and pressure the EL-WEM is designed with your comfort and safety in mind.

EasyLog

EL-WEM

a five-stage traffic light system to rate air quality from Excellent down to Inadequate, displaying colours from green through to red with each light corresponding to the status of the air quality (Excellent, Good, Fair, Poor and Inadequate). A sounder alerts those nearby if IAQ drops to Poor or Inadequate.

EL-WEM’s sophisticated sensors measure both PM2.5 and PM10 particulate matter, and also VOCs that come from paints, lacquers, and paint strippers, cleaning products, furnishings, glues, adhesives and alcohol.

to set up using the

Cloud App, the

uses

The

connected to the EasyLog Cloud, your EL-WEM can be

The world leader in force measurement

In this issue of Industry Update, we have chosen Interface Force Measurement Solutions as our Load Cell and Torque Transducer Specialists of the Year.

Interface Force Measurement Solutions (Interface) is a UK company specialising in the supply and distribution of highquality sensors and associated electronics and displays for a wide variety of industries. Working previously with clients such as Airbus, BAE Systems, and Formula One Teams, we spoke with Tony Rokins, Business Development & Pressure Mapping Specialist, who explained some of the companies well known products.

“Our product portfolio is applicable to many industries. For instance, we are well known for our high-quality pressure mapping systems that are used by many of our automotive and motorsport customers. Our sensors deliver highly accurate, repeatable measurements and many of our load cells are used by calibration houses as calibration reference devices. Our high-quality, yet competitively priced 3 and 6 axis load cells are used for many R&D, renewable energy and robotic applications.”

Reflecting on last year, Interface has faced much adversity from COVID-19. Fortunately, its sturdy business model and reliable service has enabled the company to pick up the pace and continue projects that were left postponed. “Trading conditions have

been tough, but business levels picked up strongly towards the end of the year. I think we came out of it stronger than we could have reasonably expected.”

In terms of recent developments, Tony continued, “we’ve taken some time to review our business model, how we operate on a day-to-day basis. Being responsive to our customer’s needs and being able to offer a high-quality product with strong product knowledge at a competitive price with the best possible lead times is our number one priority.”

2021 also welcomed the launch of the G-Series Load Cells. The range comprises of miniature and small sensors for industrial applications, with capacities starting from just 4.5N Newton up to 200kN with metric threads. “These are high-performance devices but aimed at more cost-conscious applications. This is a new market for us, but we are seeing increasing interest. We are launching an e-commerce

website for the G-Series in the next couple of weeks. Competitive pricing and availability from stock will be key to this new venture’s success,” stated Tony.

In the future, Interface is keen to continue its growth trajectory for 2022. We asked Tony how he felt receiving the award and what their plans are going forward, he answered, “we work hard for our customers to offer the best measurement solutions. The recognition is greatly appreciated. Long term, we are strengthening our position with our customers in our more traditional markets of aerospace, automotive, motorsport, Universities and alternative energy research.